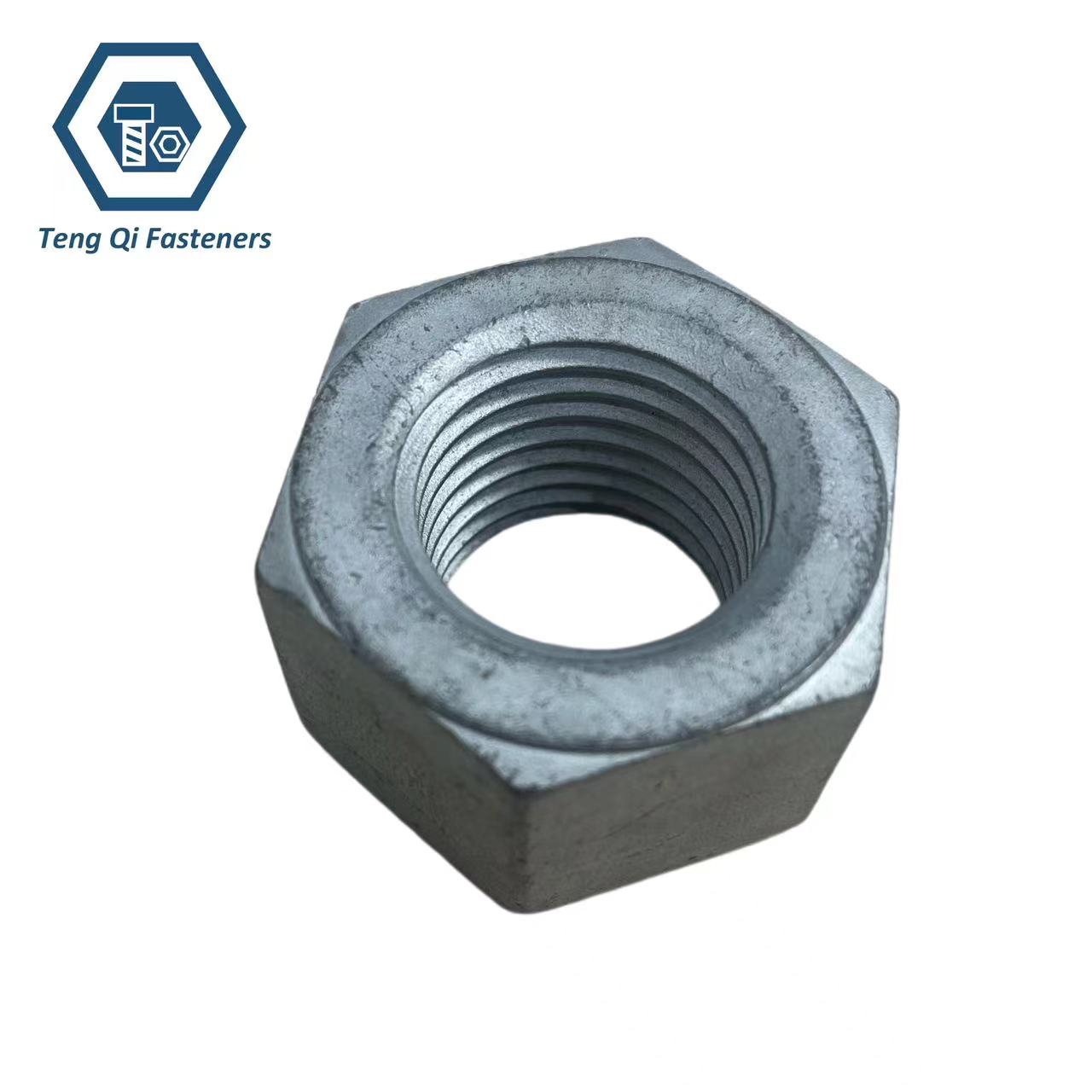

A194 American Standard Heavy Hex Nuts Supplier Exporter

Ningbo Teng Qi Fasteners Co., Ltd is a A194 American Standard heavy hex nuts supplier in China. We have deep understanding of size, material, hardness, and proof load requirements.

Our production capabilities cover A194 grades 2H, 2HM, GR.7, GR.7M, GR.8, GR.8M. Among them, A194 2H is the most requested product by customers. We have 2h nuts in stock of 1/2″-1-1/2″, which can be delivered quickly to meet customer urgent needs. Our nuts are exported to more than 20 countries including the United Kingdom, Germany, France, Poland, the United Arab Emirates, South Korea, Vietnam, the United States, Brazil, Mexico, and Canada. Mainly serving medium and large dealers and some end customers, the products have been involved in petrochemical, construction, ocean, and energy projects of large companies such as GE and Siemens for many times, and have received positive reviews from many customers and have a high reputation.

Specification of A194 American Standard Heavy Hex Nuts:

1. Diameter: The diameter of an A194 heavy hex nut refers to the size of the nut’s threaded hole. It is typically specified using a measurement like 1/2″, 5/8″, or 3/4″, indicating the inner diameter.

2. Grade: The grade of an A194 heavy hex nut signifies its strength and material properties.

3. Material: These nuts are commonly made from carbon steel or alloy steel, depending on the grade, to meet specific strength and performance requirements.

4. Surface Treatment: Surface treatment refers to any coating or finish applied to the outer surface of the nuts

| Product name | A194 Heavy Hex Nuts |

|---|---|

| Standard | ASTM A194 |

| Diameter | 1/4"-4" |

| Thread: | UNC/UNF/8UN |

| Materials: | C45 STEEL/AISI 4140 |

| Grade: | 2H/2HM/7/7M |

| Dimension: | ASME B 18.2.2, ASME B 18.2.4.6M |

| Surface treatment: | Black Oxide Coating/Zinc Plating (Electroplating)/Hot-Dip Galvanizing/Mechanical Galvanizing/Dacromet Coating/Painting or Powder Coating |

| Application Industry | Construction/Bridges/Industrial Structures/Equipment and Machinery/Infrastructure |

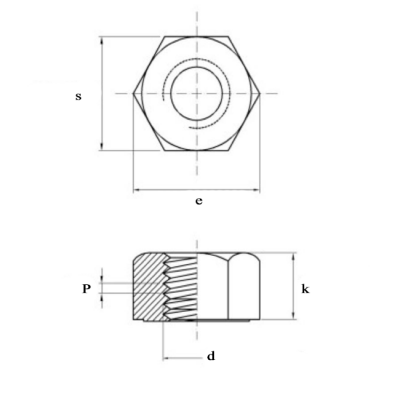

Dimension Chart of A194 Heavy Hex Nuts:

| Thread Diameter(d) | Thread Pitch(P) | Width Across Flat (s) | Width Across Corner(e) Min | Height (k) |

| 1/2 | 13 | 0.85-0.875 | 0.969-1.01 | 0.464-0.504 |

| 5/8 | 11 | 1.031-1.062 | 1.175-1.227 | 0.587-0.631 |

| 3/4 | 10 | 1.212-1.25 | 1.383-1.443 | 0.71-0.758 |

| 7/8 | 9 | 1.394-1.438 | 1.589-1.660 | 0.833-0.885 |

| 1 | 8 | 1.575-1.625 | 1.796-1.876 | 0.956-1.012 |

| 1-1/8 | 7 | 1.756-1.812 | 2.002-2.093 | 1.079-1.139 |

| 1-1/4 | 7 | 1.938-2.000 | 2.209-2.309 | 1.187-1.251 |

| 1-3/8 | 6 | 2.119-2.188 | 2.416-2.526 | 1.31-1.378 |

| 1-1/2 | 6 | 2.300-2.375 | 2.622-2.742 | 1.433-1.505 |

- RELATED NUTS LISTS:

- ISO4032 Hex Nut

- ANSI B18.2.2 Hex Nut

- AS1252 Hex Nut

- DIN6915 Hex Nut

- A194 Heavy Hex Nut

- A563 Heavy Hex Nut

- JIS1186 Hex Nut

- UNI5587 Hex Nut

- DIN6923 Flange Nut

- DIN985 Nylon Nut

- DIN982 Nylon Nut

- DIN1587 Dome Cap Nut

- DIN6334 Coupling Nut

- ASME B 18.16.6 Nylon Nuts

- GOST 5915 Hex Nut

- AS1112.1 Hex Nuts

- DIN6330 Hex Thick Nuts

Application of A194 Heavy Hex Nuts:

A194 heavy hex nuts are commonly used in various industrial applications where high-strength fastening is required. These nuts are specifically designed to be used with high-strength bolts in heavy-duty structural and mechanical assemblies. Here are some common applications:

| Industry | Details |

|---|---|

| Pressure Vessels: | In the fabrication of pressure vessels, such as boilers and tanks, A194 heavy hex nuts are used to securely fasten components together, ensuring the integrity of the vessel under high pressure. |

| Pipeline and Piping Systems: | These nuts find applications in the oil and gas industry for connecting pipelines and various piping systems. The high strength of A194 heavy hex nuts ensures the reliability of these critical connections. |

| Power Generation: | In power plants, especially those dealing with high-pressure steam, A194 heavy hex nuts are used in the assembly of turbines, generators, and other components to withstand the demanding conditions. |

| Heavy Machinery: | A194 heavy hex nuts are utilized in the assembly of heavy machinery and equipment where the fasteners need to endure substantial loads and vibrations. |

| Mining Equipment: | Due to their high-strength characteristics, these nuts are suitable for securing components in mining machinery and equipment subjected to rugged conditions. |

| Railroad Construction: | A194 heavy hex nuts are employed in the construction and maintenance of railroads, ensuring the secure fastening of rails and other components. |

Manufacturing Quality Control of A194 Heavy Hex Nut:

| Control Method | Detail |

|---|---|

| Material Inspection: | Verify the material's composition, heat treatment, and quality upon receipt. Conduct metallurgical analysis to ensure the material properties meet the standards. |

| Process Control: | Implement strict process control measures for heat treatment, machining, threading, and any other manufacturing steps. Maintain consistent process parameters to ensure uniform quality. |

| Inspection Points: | Introduce inspection points at various stages of manufacturing to check for defects, dimensions, and quality. Inspect threading, dimensions, surface finish, and other critical parameters. |

| Sampling and Testing: | Regularly sample products for testing, such as tensile testing, hardness testing, and metallurgical analysis, to ensure they meet the required specifications. |

| Thread Inspection: | Thoroughly inspect threading using proper thread gauges to ensure accurate dimensions and fit with mating components. |

| Traceability: | Implement a traceability system to track each fasteners journey from raw material to final product. This aids in accountability and recalls if necessary. |