American Standard A325 Steel Structural Heavy Hex Bolts Supplier

Ningbo Teng Qi Fasteners Co., Ltd is a A325 heavy hex bolts supplier in China. A325 Heavy Hex Bolts are high-strength bolts designed for use in structural steel connections. They are defined by the ASTM A325 specification, which sets the standards for these bolts. The “Type 1” designation refers to the specific configuration and requirements of these bolts.

Here are some key characteristics of A325 Type 1 structural heavy hex bolt:

| Key features | Description |

|---|---|

| High Strength: | A325 Type 1 bolts are made from medium carbon steel and undergo a heat treatment process to achieve high tensile strength. They are capable of providing reliable and secure connections in structural applications. |

| Heavy Hex Head: | These bolts feature a heavy hex head, which provides a larger bearing surface and enhanced load distribution compared to standard hex bolts. The heavy hex head also facilitates tightening with a larger wrench or socket. |

| Pre-Installation Verification: | A325 Type 1 bolts is the requirement for pre-installation verification. This involves verifying the length of the bolt protrusion beyond the nut to ensure proper engagement and tensioning during installation. |

A325 Type 1 structural bolts are commonly used in construction, bridges, and other structural applications where high-strength connections are required. They provide reliable and durable fastening, contributing to the overall integrity and safety of the structures. It’s important to follow the specific installation procedures and guidelines outlined in the ASTM A325 specification and consult with structural engineers to ensure proper use of these bolts in specific applications.

Specification of American Standard A325 Heavy Hex Bolts:

A325 heavy hex bolts are high-strength structural bolts commonly used in construction. They typically have a medium carbon or alloy steel composition. The ASTM A325 standard outlines specifications for these bolts, including size range, mechanical properties, and testing requirements. They’re designed for use in structural connections and have a defined thread length and heavy hexagonal head for enhanced load-bearing capacity.

| Product name | ASTM A325 Heavy Hex Bolts |

|---|---|

| Diameter | 1/2″ – 1-1/2″ |

| Dimension Standard | ASME B18.2.6 |

| Head Type | Heavy Hex Head |

| Bolt Length | 1-1/2"-10" |

| Class | Type 1 |

| Hardness | 25-34HRC |

| Tension Strength | 120 ksi |

| Material | C45/40Cr/AISI4140 |

| Compatible nuts/washers | A563 DH Heavy Hex Nut/F436 Washer |

| Surface treatment | Black Oxide Coating/Zinc Plating (Electroplating)/Hot-Dip Galvanizing/Mechanical Galvanizing/Dacromet Coating/Painting or Powder Coating |

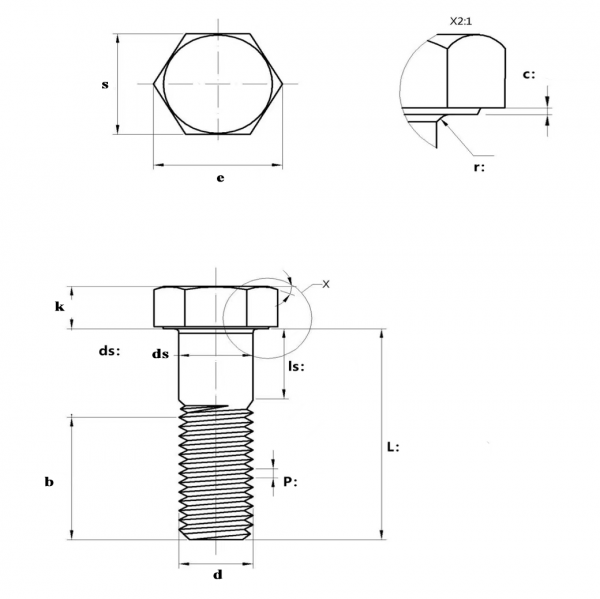

Dimension Chart:

Dimensions of A325 heavy hex bolts are specified by ASME B18.2.6 standards. These standards provide detailed specifications for various parameters, including thread length, head diameter, and head height, ensuring uniformity and reliability in bolt manufacturing.

| Thread Diameter(d) | Body Diameter(ds) | Width Across Flat (s) | Width Across Corner(e) Min | Head Height (k) | Radius(r) Min | Thread Length(b) |

| 1/2 | 0.482-0.515 | 0.85-0.875 | 0.969-1.01 | 0.302-0.323 | 0.009-0.031 | 1 |

| 5/8 | 0.605-0.64 | 1.031-1.062 | 1.175-1.227 | 0.378-0.403 | 0.021-0.062 | 1.25 |

| 3/4 | 0.729-0.768 | 1.212-1.25 | 1.383-1.443 | 0.455-0.483 | 0.021-0.062 | 1.38 |

| 7/8 | 0.852-0.895 | 1.394-1.438 | 1.589-1.660 | 0.531-0.563 | 0.021-0.062 | 1.5 |

| 1 | 0.976-1.022 | 1.575-1.625 | 1.796-1.876 | 0.591-0.627 | 0.062-0.093 | 1.75 |

| 1-1/8 | 1.098-1.149 | 1.756-1.812 | 2.002-2.093 | 0.658-0.718 | 0.062-0.093 | 2 |

| 1-1/4 | 1.223-1.277 | 1.938-2.000 | 2.209-2.309 | 0.749-0.813 | 0.062-0.093 | 2 |

| 1-3/8 | 1.345-1.404 | 2.119-2.188 | 2.416-2.526 | 0.810-0.878 | 0.062-0.093 | 2.25 |

| 1-1/2 | 1.470-1.531 | 2.300-2.375 | 2.622-2.742 | 0.902-0.974 | 0.062-0.093 | 2.25 |

Mechanical property:

| Specification | Tensile | Yield | Elongation % | Reduction Area % | Hardness (HRC) |

| A325 Type 1 Bolts | 120 ksi (min) | 92 ksi(min) | 14 (min) | 35 (min) | 25-34 |

Chemical Composition:

| Chemical Elements | Composition % |

|---|---|

| Carbon | 0.30-0.52 |

| Manganese | 0.60 min |

| Phosphorus | 0.035 max |

| Sulfur | 0.040 max |

| Silicon | 0.15 – 0.30 |

| Boron | 0.003 max |

- RELATED BOLTS LISTS:

- HEX BOLTS

- HEAVY HEX BOLTS

- DIN931 HEX BOLTS

- AS1252 HEX BOLTS

- DIN6914 HEX BOLTS

- ASME B 18.2.1 HEX BOLTS

- DIN933 HEX BOLTS

- A490 HEAVY HEX BOLTS

- RELATED NUTS LIST:

- HEX NUTS

- HEAVY HEX NUTS

- ISO4032 HEX NUTS

- DIN934 HEX NUTS

- A194 HEAVY HEX NUTS

- A563 HEAVY HEX NUTS

- THREADED ROD LIST:

- DIN975 THREADED RODS

- A193 B7 STUD BOLTS

Production Process of A325 Heavy Hex Bolts:

Here’s an introduction to the production process of A325 heavy hex bolts:

| Production Procession of Hex Bolts |

|---|

| 1. Material Preparation: - Round wire steel undergoes phosphating and wire drawing to required dimension. This step ensures that the material is appropriately sized for the subsequent forming process. |

| 2. Forming: Size smaller M24 or 1": Cold heading -Feed the cut material into a cold heading machine, which uses punches and dies to shape the material at room temperature. The machine compresses the material, forming it into the desired hexagonal shape for the bolt head. Size Larger than M24 or 1": Hot Forging - This process involves heating the material to a high temperature and shaping it using dies or molds. In the context of hex bolts, hot forging imparts the desired hexagonal shape to the head of the bolt. |

| 3. Thread rolling: - Use a thread rolling machine for thread rolling. Product is placed between two rollers and enough pressure is applied to cause the material to thread between the rollers. |

| 4. Heat Treatment: - Heat treatment is applied to improve the hardness and strength of the hex bolts. |

| 5. Surface Treatment: - The final step involves surface treatment, enhancing corrosion resistance and providing a polished finish. |

Quality control of A325 Heavy Hex Bolts:

Quality control of A325 heavy hex bolts, which are typically high-strength structural bolts used in construction, involves rigorous measures to ensure they meet industry standards. Here are some key aspects of quality control:

| Control Method | Detail |

|---|---|

| Material Inspection: | Verify the material's composition, heat treatment, and quality upon receipt. Conduct metallurgical analysis to ensure the material properties meet the standards. |

| Process Control: | Implement strict process control measures for heat treatment, machining, threading, and any other manufacturing steps. Maintain consistent process parameters to ensure uniform quality. |

| Inspection Points: | Introduce inspection points at various stages of manufacturing to check for defects, dimensions, and quality. Inspect threading, dimensions, surface finish, and other critical parameters. |

| Sampling and Testing: | Regularly sample products for testing, such as tensile testing, hardness testing, and metallurgical analysis, to ensure they meet the required specifications. |

| Thread Inspection: | Thoroughly inspect threading using proper thread gauges to ensure accurate dimensions and fit with mating components. |

| Traceability: | Implement a traceability system to track each fasteners journey from raw material to final product. This aids in accountability and recalls if necessary. |

Application of A325 Heavy Hex Bolts:

A325 heavy hex bolts are high-strength structural bolts specifically designed for use in structural steel connections. These bolts, along with their counterpart nuts and washers, are commonly utilized in various construction and engineering applications where a reliable and robust fastening solution is required. Here are some key applications of A325 heavy hex bolts:

| Application | Details |

|---|---|

| Building Construction: | A325 bolts are extensively used in the construction of buildings, including commercial structures, residential buildings, and industrial facilities. They play a crucial role in connecting structural steel elements such as beams, columns, and braces. |

| Bridges and Infrastructure: | In the construction and maintenance of bridges and other infrastructure projects, A325 heavy hex bolts are employed to join critical components, ensuring the structural integrity and stability of the overall structure. |

| Towers and Communication Structures: | A325 bolts are used in the assembly of communication towers, electrical transmission towers, and other tall structures. They provide a secure fastening method for connecting tower sections and maintaining stability. |

| Power Generation: | In power plants, including both traditional and renewable energy facilities, A325 bolts are used for connecting structural components, supporting equipment, and ensuring the overall stability of power generation structures. |

| Heavy Equipment Manufacturing: | A325 bolts are employed in the manufacturing of heavy equipment, such as cranes, excavators, and mining machinery. They provide reliable fastening for components that endure heavy loads and vibrations. |

| Railroad Infrastructure: | A325 heavy hex bolts are used in the construction and maintenance of railroad tracks and related infrastructure. They provide a secure connection for rail components, ensuring safety and stability. |

FAQ about A325 Heavy Hex Bolts Manufacturer:

1.What’s the price of type1 of A325 heavy hex bolts?

The wholesale price of A325 heavy hex bolts is 1300-1800usd/ton. The material price of steel will fluctuate frequently, and the price is different for different surface treatment/quantity, so please send the inquiry to our email for the specific price. Emai: info@china-bolts.com

2.How many days does it take you to produce a container of bolts?

Our daily production capacity of cold heading and hot forging bolts is about 30 tons, but due to the arrangement of materials, heat treatment, surface treatment, order scheduling takes time. The average delivery time of bolts for a container is 30-40 days.

3.What countries do you export A325 heavy hex bolts to?

We mainly export A325 heavy duty bolts to USA, Brazil, Argentina. The main service customers are medium and large fastener dealers, wholesalers, our company generally does not serve the end customer. Our company has stable customers in Ohio, Texas, South Carolina, Indiana, California, and Michigan in the United States.

4. Do you have a minimum order quantity requirement?

Yes, the MOQ we usually produce is about one ton.