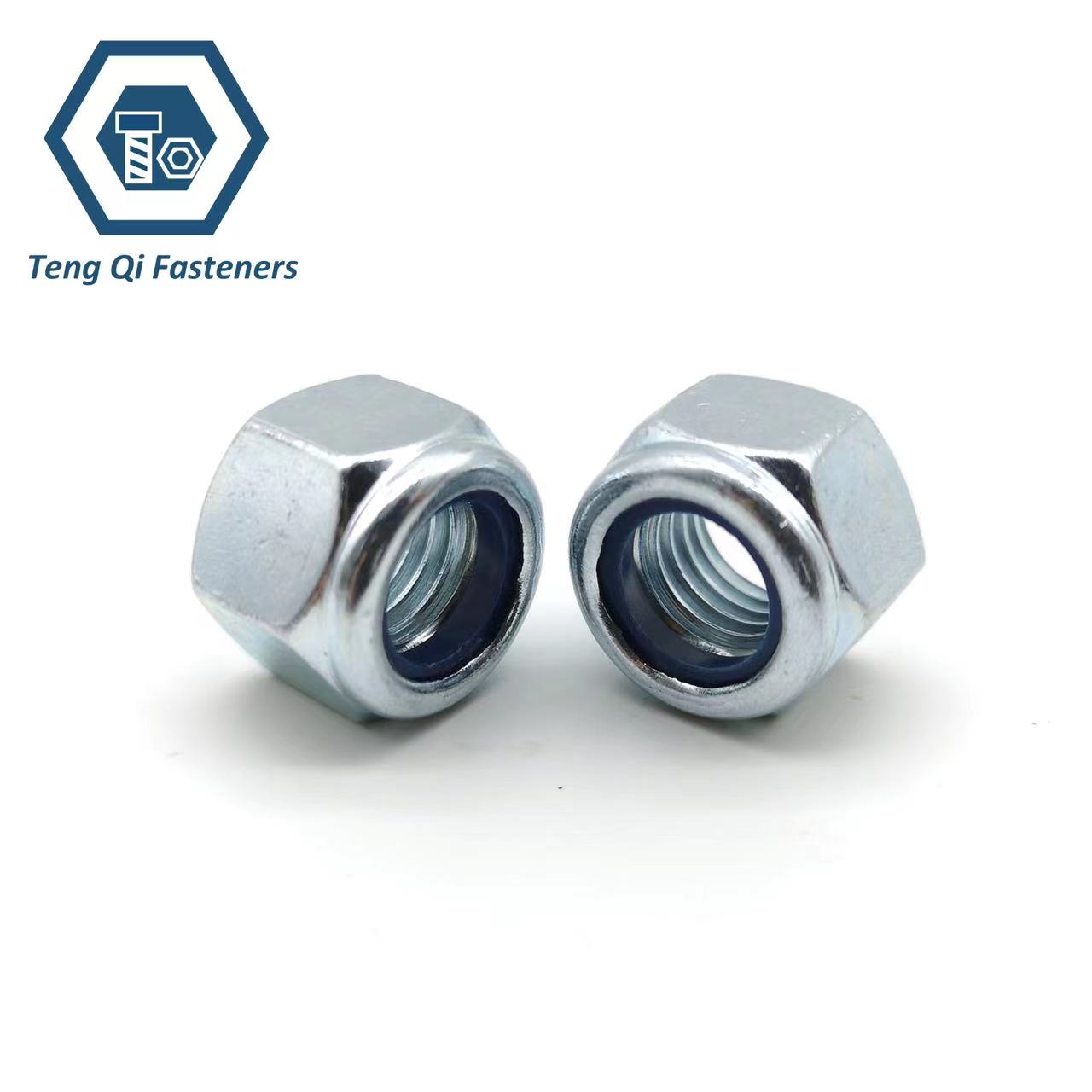

DIN985 Nylon Lock Nuts Supplier In China

Ningbo Teng Qi Fasteners Co., Ltd is a supplier of DIN 985 nylon lock nuts, located in Ningbo, with 20 years experience and technology accumulation. Our products cover a variety of specifications and sizes, including standard specifications and special specifications customized according to customer needs to meet the needs of different industries and application fields. In our factory, we focus on quality control and adopt a strict quality management system to ensure that every link reaches the highest standards.

We have an experienced, efficient and professional production team. They not only have solid technical skills, but also respond to customer needs in a timely manner to ensure on-time delivery of orders. Our products are widely used in machinery manufacturing, automotive industry, electronic equipment, aerospace and other fields to ensure the safe connection of equipment and components. Whether it’s a small order or a large bulk purchase, we are able to provide a solution that meets our customers’ needs. Customer satisfaction is our unremitting goal. We will wholeheartedly provide you with high-quality products and services, and work with you to create a better future!

Specification of DIN985 Nylon Nut:

The specification of DIN985 nylon nut include the following details:

| Product name | DIN985 Nylon Nut |

|---|---|

| Diameter: | M3-M48 |

| Material: | Class 5: Q195/Q235/ML08AL Low Carbon Steel Class 8: 35K/45K Medium Carbon Steel Class 10: 45K/10B21/40Cr A2-70: SS304 A4-80: SS316 |

| Surface Treatment | Zinc Plated/Dacromet/Acid pickling |

| Packaging: | Boxes/cartons into wooden pallets |

| Application: | Construction/Agricultural Machinery/Industrial Structures/Equipment and Machinery/Infrastructure |

- RELATED NUT LISTS:

- DIN6334 Hexagon Coupling Nuts

- ASME/ANSI B 18.2.2 Hex Slotted Nuts/Castle Nuts

- ASME/ANSI B18.2.2 Hex Flange Nuts

- Lock Nuts

- IFI145 Flange Nuts

- DIN982 Nylon Lock Nuts

- ASME B 18.16.6 Nylon Nuts

- HEX NUT

- JIS 1186 Hex Nuts

- DIN934 Hex Nuts

- A194 Hex Nuts

- A563 Hex Nuts

- DIN6915 Hex Nuts

- GOST 28919 Thick Hex Nuts

- GOST R 52645 Structural Hex Nuts

- GOST 5915 Hex Nut

- UNI5588 Hex Nuts

- UNI5587 Thick Hex Nuts

- UNI5713 Hex Nuts

- AS1112.1 Hex Nuts

- AS1252 Hex Nuts

- AS/NZS 2451 Hex Nuts

- AS/NZS 2465 Hex Nuts

- DIN6330 Hex Thick Nuts

- ASME/ANSI B 18.2.2 Hex Thick Nuts

Chemical Composition of class5 8 10 12 Nylon Nuts:

| Property class | Carbon% | Manganese%, min | Phosphorus%, max | Sulfur%, max |

| 5,6 | 0.5 max | - | 0.11 | 0.15 |

| 8 | 0.58 max | 0.25 | 0.06 | 0.15 |

| 10 | 0.58 max | 0.3 | 0.048 | 0.058 |

Mechanical property:

| Thread Diameter | Property Class | |||||||

| 5 | 8 | 10 | 12 | |||||

| Proof Stress | Vickers Hardness HV | Proof Stress | Vickers Hardness HV | Proof Stress | Vickers Hardness HV | Proof Stress | Vickers Hardness HV | |

| Up to M4 | 520 | 130-302 | 800 | 170 | 1040 | 272-353 | 1150 | 295-353 |

| M4-M7 | 580 | 130-302 | 810 | 188 | 1040 | 272-353 | 1150 | 295-353 |

| M7-M10 | 590 | 130-302 | 830 | 1040 | 272-353 | 1160 | 295-353 | |

| M10-M16 | 610 | 130-302 | 840 | 1050 | 272-353 | 1190 | 295-353 | |

| M16-M39 | 630 | 146-302 | 920 | 233 | 1060 | 272-353 | 1200 | 295-353 |

Dimension Chart of DIN985 Nylon Nuts:

| Thread Diameter | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 |

| P | 0.5 | 0.7 | 0.8 | 1 | 1|1.25 | 1|1.25|1.5 | 1.25|1.5|1.75 | 1.5|2 | 1.5|2 | 1.5|2|2.5 |

| e min | 6.01 | 7.66 | 8.79 | 11.05 | 14.38 | 18.9 | 21.1 | 24.49 | 26.75 | 29.56 |

| h max | 4 | 5 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18.5 |

| h min | 3.7 | 4.7 | 4.7 | 5.7 | 7.64 | 9.64 | 11.57 | 13.3 | 15.3 | 17.66 |

| k min | 2.4 | 2.9 | 3.2 | 4 | 5.5 | 6.5 | 8 | 9.5 | 10.5 | 13 |

| s max | 5.5 | 7 | 8 | 10 | 13 | 17 | 19 | 22 | 24 | 27 |

| s min | 5.32 | 6.78 | 7.78 | 9.78 | 12.73 | 16.73 | 18.67 | 21.67 | 23.67 | 26.16 |

| Thread Diameter | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M48 |

| P | 1.5|2|2.5 | 1.5|2|2.5 | 2|3 | 2|3 | 2|3.5 | 2|3.5 | 3|4 | 3|4 | 3|4.5 | 3|5 |

| e min | 32.95 | 35.03 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 72.09 | 82.6 |

| h max | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | 48 |

| h min | 18.7 | 20.7 | 22.7 | 25.7 | 28.7 | 31.4 | 34.4 | 37.4 | 40.4 | 46.4 |

| k min | 14 | 15 | 15 | 17 | 19 | 22 | 25 | 27 | 29 | 36 |

| s max | 30 | 32 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 75 |

| s min | 29.16 | 31 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.8 | 73.1 |

Application of DIN985 Nylon Nuts:

Nylon nuts, conforming to the DIN 985 standard, are indispensable fasteners renowned for their reliability and versatility across diverse industries. These nuts, featuring a nylon insert, offer secure fastening solutions and resistance to loosening, making them essential components in a wide array of applications.

| Application | Details |

|---|---|

| Automotive Industry: | In automotive manufacturing, DIN 985 nylon nuts secure critical components such as engine parts, chassis, and interior fittings. Their ability to withstand vibrations ensures stable fastening, contributing to vehicle safety and reliability, even in high-speed or off-road conditions. |

| Machinery and Equipment: | Within industrial machinery, nylon nuts play a crucial role in securing moving parts, electrical components, and structural elements. Their resistance to vibration helps maintain machine integrity, preventing loosening during continuous operation, and ensuring operational efficiency. |

| Construction: | Nylon nuts find extensive use in construction applications, securing structural elements, scaffolding, and fixtures. Their durability and resistance to corrosion make them ideal for long-term installations in various building projects, ensuring structural integrity and safety. |

| Electronics: | Nylon nuts are vital in the electronics industry, securing circuit boards, enclosures, and mounting hardware. Their non-conductive properties prevent electrical shorts and provide insulation between components, ensuring reliable and safe operation in electronic devices and systems. |

| Renewable Energy: | In wind and solar power installations, nylon nuts secure turbine blades, solar panels, and mounting hardware. Their durability and resistance to environmental factors contribute to the longevity and efficiency of renewable energy systems, supporting sustainable energy production. |

| Electronics: | In certain electronic applications where metric fasteners are specified, ISO 4032 hex nuts may be used for securing components. |