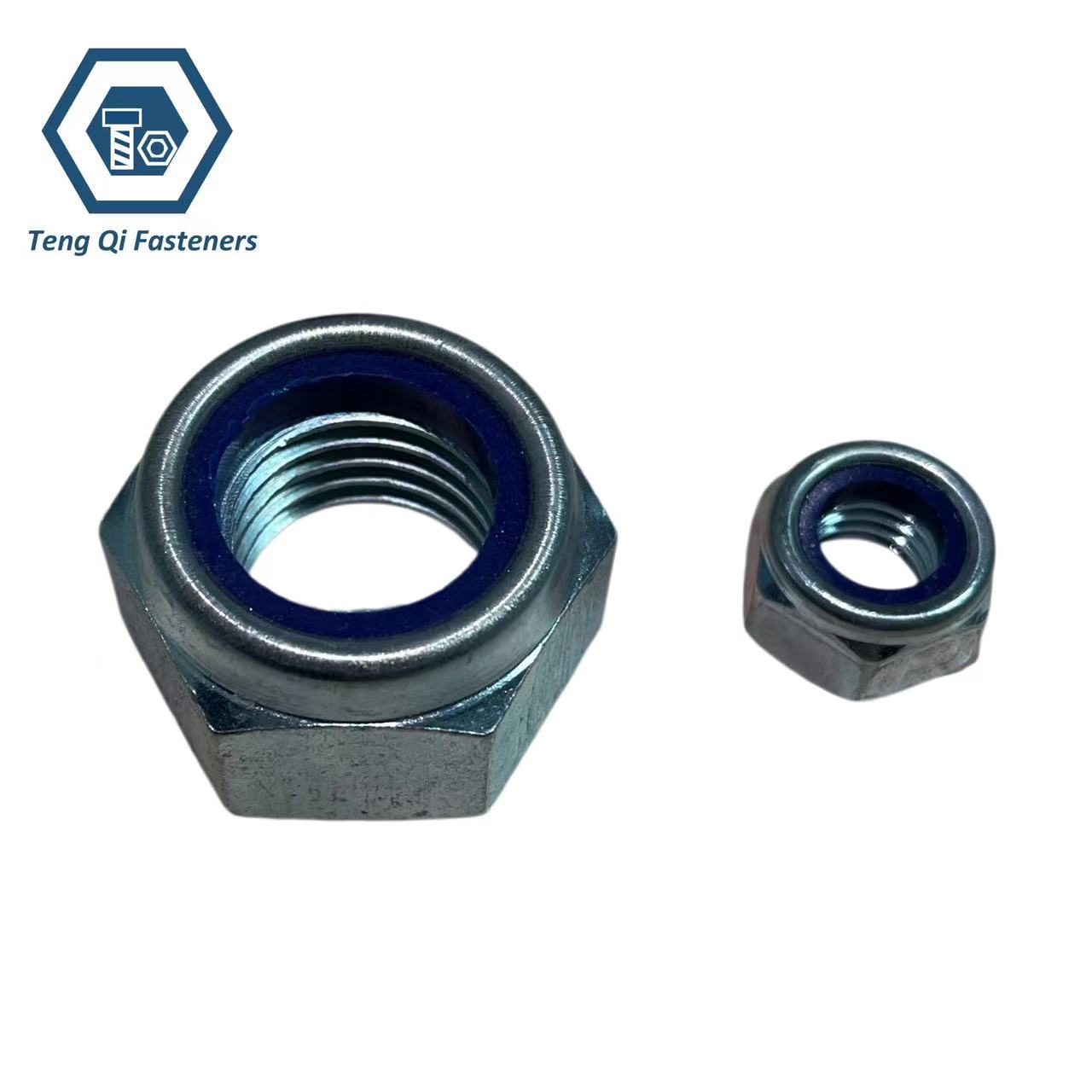

ASME B18.16.6 American Standard Nylon Nuts Manufacturer In China

Ningbo Teng Qi Fasteners Co., Ltd is a ASME B18.16.6 nylon nuts supplier in china. Nylon insert locknuts are two-piece construction hex nuts and hex flange nuts that derive their prevailing torque characteristics from a full ring of nylon material, located and retained in the nut under its top surface. We specialize in produce nylon nuts from carbon steel/stainless steel, ensuring dimension and mechanical property in every product. Our offerings span a comprehensive array of dimensional styles, including NE (1/4″-1-1/2″.), NTE (1/4″-1-1/2″.), NU (from 1/4″ in. to 3″), NTU (1/4″ in. to 3″), NM (from #2 to #12), and NTM (from #2 to #12). Within these styles, our nylon nuts are meticulously graded as N2, N5, and N8, ensuring suitability for a wide range of applications. With an unwavering commitment to quality and precision, we stand as your trusted partner in delivering excellence in ASME B18.16.6 nylon nuts.

Specification American Standard Asme B18.16.6 Nylon Nuts:

| Product name | Asme b 18.16.6 Nylon Nuts |

|---|---|

| Thread: | Unified thread form coarse, fine, or 8 thread series (UNC, UNF, or 8-UN) Class 2B in accordance with ASME B1.1 |

| Materials: | Carbon Steel Q235/C35/C45 |

| Grade: | N2,N5,N8 |

| Styles and Dimensions: | NE (1/4"-1-1/2".), NTE (1/4"-1-1/2".), NU (from 1/4" in. to 3"), NTU (1/4" in. to 3"), NM (from #2 to #12), and NTM (from #2 to #12) |

| Surface treatment: | Zinc Plated/Dacromet |

Chemical Composition

| Nylon Nut Grade | C(Max) | Mn(Min) | P(Max) | S(Max) |

|---|---|---|---|---|

| N2 | 0.47 | - | 0.12 | 0.15 |

| N5 | 0.55 | 0.3 | 0.05 | 0.15 |

| N8 | 0.55 | 0.3 | 0.04 | 0.05 |

Hardness:

| Nylon Nut Grade | Locknut Size | Rockwell Hardness |

|---|---|---|

| N2,N5 | 1/4"-1-1/2" | C28 (max) |

| N8 | 1/4"-5/8" | C24-C32 |

| 3/4"-1" | C26-C34 | |

| 1-1/8"-1-1/2" | C26-C36 |

Proof Load:

| Grade N2 | Grade N5 | Grade N8 | Prevailing Torque | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nut Size | Thread Per Inch | Proof Load | Clamp Load | Proof Load | Clamp Load | Proof Load | Clamp Load | First Install (lb) Max | First removal (lb) Min | Third removal (lb) Min |

| #4 | 40 | 540 | 250 | 720 | 380 | 910 | 550 | 4 | 1 | 0.2 |

| #6 | 32 | 820 | 370 | 1100 | 580 | 1350 | 810 | 8 | 1.5 | 0.5 |

| #8 | 32 | 1250 | 580 | 1700 | 900 | 2100 | 1250 | 12 | 2 | 0.5 |

| #10 | 24 | 1550 | 720 | 2100 | 1100 | 2600 | 1550 | 17 | 2.5 | 1 |

| #12 | 24 | 2200 | 1000 | 2900 | 1550 | 3650 | 2200 | 27 | 3.5 | 1 |

| 1/4″ | 20 | 2900 | 1300 | 3800 | 2000 | 4750 | 2850 | 40 | 5 | 1.5 |

| 5/16″ | 18 | 4700 | 2150 | 6300 | 3350 | 7850 | 4700 | 80 | 8 | 2.5 |

| 3/8″ | 16 | 7000 | 3200 | 9300 | 4950 | 11600 | 6950 | 110 | 12 | 4 |

| 7/16″ | 14 | 9550 | 4400 | 12800 | 6800 | 15900 | 9600 | 135 | 17 | 5 |

| 1/2″ | 13 | 12800 | 5850 | 17000 | 9050 | 21300 | 12800 | 204 | 22 | 7.5 |

| 9/16″ | 12 | 16400 | 7550 | 21800 | 11600 | 27300 | 16400 | 300 | 30 | 10 |

| 5/8″ | 11 | 20300 | 9300 | 27200 | 14500 | 33900 | 20300 | 420 | 39 | 12.5 |

| 3/4″ | 10 | 30000 | 13800 | 40100 | 21300 | 50100 | 30100 | 540 | 58 | 20 |

| 7/8″ | 9 | 41600 | 12400 | 55400 | 29500 | 69300 | 41600 | 840 | 88 | 30 |

| 1″ | 8 | 54500 | 15000 | 72700 | 38700 | 90900 | 54600 | 1080 | 120 | 40 |

| 1 1/8″ | 7 | 68700 | 18900 | 80100 | 42100 | 115000 | 69000 | 1200 | 150 | 50 |

| 1 1/4″ | 7 | 87200 | 24000 | 101700 | 53500 | 145000 | 87000 | 1320 | 188 | 60 |

| 1 3/8″ | 6 | 104000 | 28700 | 121300 | 63800 | 173000 | 104000 | 1620 | 220 | 70 |

| 1 1/2″ | 6 | 126000 | 34800 | 147500 | 77600 | 211000 | 127000 | 1800 | 260 | 90 |

- RELATED NUT LISTS:

- DIN6334 Hexagon Coupling Nuts

- ASME/ANSI B 18.2.2 Hex Slotted Nuts/Castle Nuts

- ASME/ANSI B18.2.2 Hex Flange Nuts

- Lock Nuts

- IFI145 Flange Nuts

- DIN982 Nylon Lock Nuts

- DIN985 Nylon Lock Nuts

- HEX NUT

- JIS 1186 Hex Nuts

- DIN934 Hex Nuts

- A194 Hex Nuts

- A563 Hex Nuts

- DIN6915 Hex Nuts

- GOST 28919 Thick Hex Nuts

- GOST R 52645 Structural Hex Nuts

- GOST 5915 Hex Nut

- UNI5588 Hex Nuts

- UNI5587 Thick Hex Nuts

- UNI5713 Hex Nuts

- AS1112.1 Hex Nuts

- AS1252 Hex Nuts

- AS/NZS 2451 Hex Nuts

- AS/NZS 2465 Hex Nuts

- DIN6330 Hex Thick Nuts

- ASME/ANSI B 18.2.2 Hex Thick Nuts

Application of Asme B18.16.6 Nylon Nuts:

| Industry | Application |

|---|---|

| Mechanical and Automotive Industries: | These nylon nuts are widely used in mechanical and automotive applications where vibration resistance is crucial. They provide secure fastening in assemblies subjected to constant movement and vibration. |

| Construction and Infrastructure: | In construction projects and infrastructure development, ASME B18.16.6 nylon nuts are employed for fastening structural components, equipment, and machinery. Their resistance to corrosion and ability to maintain torque make them reliable in harsh environments. |

| Electrical and Electronics: | Nylon nuts are utilized in electrical and electronic equipment manufacturing for securing components and assemblies. Their non-conductive nature prevents electrical conductivity, making them suitable for applications where insulation is required. |

| Plumbing and HVAC Systems: | These nuts are used in plumbing and HVAC systems for joining pipes, fittings, and fixtures. Their resistance to corrosion and ability to maintain tight seals contribute to the efficiency and longevity of such systems. |

| Marine and Nautical Applications: | ASME B18.16.6 nylon nuts are suitable for marine and nautical environments due to their resistance to saltwater corrosion. They are used in boat building, ship repair, and marine equipment manufacturing. |

Quality Control:

| Control Method | Detail |

|---|---|

| Material Inspection: | Verify the material's composition, heat treatment, and quality upon receipt. Conduct metallurgical analysis to ensure the material properties meet the standards. |

| Process Control: | Implement strict process control measures for heat treatment, machining, threading, and any other manufacturing steps. Maintain consistent process parameters to ensure uniform quality. |

| Inspection Points: | Introduce inspection points at various stages of manufacturing to check for defects, dimensions, and quality. Inspect threading, dimensions, surface finish, and other critical parameters. |

| Sampling and Testing: | Regularly sample products for testing, such as tensile testing, hardness testing, and metallurgical analysis, to ensure they meet the required specifications. |

| Thread Inspection: | Thoroughly inspect threading using proper thread gauges to ensure accurate dimensions and fit with mating components. |

| Traceability: | Implement a traceability system to track each fasteners journey from raw material to final product. This aids in accountability and recalls if necessary. |