ISO4017 Hex Bolts Supplier Exporter In China

Ningbo Teng Qi Fasteners Co., Ltd is a leading ISO4017 hex bolts supplier in China. ISO4017 is an international standard that specifies the dimensions, mechanical properties, and other relevant requirements for hexagon head screws, commonly known as hex bolts. These bolts typically have a threaded shank with a hexagonal head on one end, allowing them to be tightened using a wrench or a socket.

ISO4017 hex bolts are used in a wide range of applications, including construction, machinery, automotive, and various industrial uses. The standard covers bolts made from different materials, including steel, stainless steel, and other alloys. It provides specifications for various characteristics such as thread diameter, pitch, length, and mechanical properties like tensile strength and hardness.

In essence, ISO4017 hex bolts ensure uniformity and interchangeability across different manufacturers and industries, making them a widely accepted choice for securing components together in various assemblies.

Specification:

ISO 4017 defines the standard for hexagon head bolts with full thread. This specification includes details such as dimensions, material options (like steel and stainless steel), and the potential for both coarse and fine thread pitches. The hexagon head design facilitates easy tightening, making these bolts a reliable choice for diverse industrial applications. ISO 4017 standard specifies the characteristics of hexagon head bolts with threads from M1.6 to M64. Here are detailed specifications for ISO 4017 hex bolts:

| Product name | ISO4017 Hex Bolts |

|---|---|

| Thread | The thread specifications for ISO 4017 hex bolts follow the ISO metric screw thread standards. Here are the key details: 1. **Thread Pitch:** The thread pitch is the distance between adjacent threads and is specified in millimeters. Different sizes of ISO 4017 hex bolts will have different thread pitches. 2. **Thread Diameter:** The thread diameter is the nominal diameter of the threaded section of the bolt and is typically expressed in millimeters. For example, a notation for a thread specification might look like M12 x 1.75, where: - "M" stands for metric, - "12" is the nominal diameter of the thread in millimeters, and - "1.75" is the pitch of the thread in millimeters. |

| Length | ISO 4017 specifies metric hexagon head bolts with a full thread. The length of ISO 4017 hex bolts is typically measured from the underhead bearing surface to the extreme end of the bolt. |

| Head Type | Hexagonal head with six flat sides, designed for easy tightening with a wrench or socket. |

| Hardness | Class4.8: 130-220HV Class8.8: d≤M16 22-32HRC Class8.8: d>M16 23-34HRC Class10.9: 32-39HRC Class12.9: 39-44HRC |

| Class | Class4.8/8.8/10.9/12.9 A2-70 A2-80 A4-70 A4-80 A4-100 |

| Tension Strength | Class 4.8: 400MPA Class 8.8: 800MPA Class 10.9:1000MPA Class 12.9: 1200MPA A2-70: 700MPA A2-80; 800MPA A4-70: 700MPA A4-80: 800MPA |

| Material | ISO 4017 hex bolts can be made from various materials, including carbon steel, alloy steel, stainless steel, or other materials. The specific material should conform to the relevant material standards. |

| Manufacturing Process | wire drawing, cold heading/hot forging, thread rolling, heat treatment, surface treatment |

| Surface treatment | Black Oxide Coating/Zinc Plating (Electroplating)/Hot-Dip Galvanizing/Mechanical Galvanizing/Dacromet Coating/Painting or Powder Coating |

| Application Industry | Construction/Machinery/Automotive/Infrastructure/Electrical and Electronics/Furniture/Marine and Offshore |

- RELATED BOLTS LISTS:

- HEX BOLTS

- HEAVY HEX BOLTS

- DIN933 HEX BOLTS

- AS1252 HEX BOLTS

- DIN6914 HEX BOLTS

- ASME B 18.2.1 HEX BOLTS

- A325 HEAVY HEX BOLTS

- A490 HEAVY HEX BOLTS

- RELATED NUTS LIST:

- HEX NUTS

- HEAVY HEX NUTS

- ISO4032 HEX NUTS

- DIN934 HEX NUTS

- A194 HEAVY HEX NUTS

- A563 HEAVY HEX NUTS

- THREADED ROD LIST:

- DIN975 THREADED RODS

- A193 B7 STUD BOLTS

Dimension Chart of ISO4017 Hex Bolt:

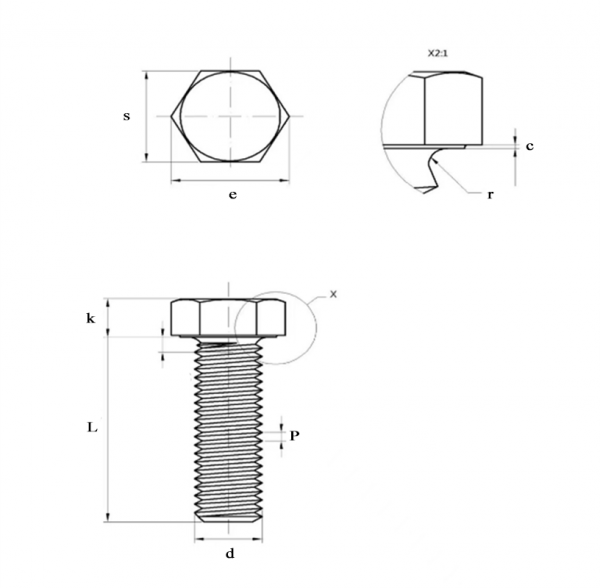

SO 4017 provides dimensions for hex bolts across a range of sizes, from M1.6 to M64. This includes specifications for the head width across flats (the distance between two parallel surfaces on opposite sides of the head) and the head height (the distance from the bearing surface to the top of the head). Here’s an explanation of the dimensions included in chart:

1. Thread Size:

– The thread size refers to the diameter and pitch of the threads on the bolt. It is a critical dimension that determines compatibility with nuts and threaded holes.

2. Across Flats (AF) – Hex Head:

– Across flats (AF) is the distance measured from one flat side of the hexagon head to the opposite flat side. It indicates the size of the wrench or socket needed for tightening.

3. Across Corners (AC) – Hex Head:

– Across corners (AC) is the distance measured from one corner of the hexagon head to the opposite corner. It provides an alternative measure for the size of the hex head.

4. Head Thickness – Hex Head:

– The head thickness is the distance measured from the bottom of the hexagon head to the underside of the bolt head. It influences how the bolt fits into recessed or countersunk holes.

5. Rounding Radius (R):

– Rounding radius (R) represents the radius of the curved corners on the hexagon head. It contributes to the overall design, providing a smooth transition from the flat sides to the corners.

The dimensions of ISO 4017 hex bolts vary depending on the size and thread pitch. Here’s a general representation of dimensions for ISO 4017 hex bolts with some common sizes:

| Thread Diameter(d) | Thread Pitch(P) | Width Across Flat (s) | Width Across Corner(e) Min | Head Height (k) | Radius(r) Min | Washer Face Thickness(c) |

| M1.6 | 0.35 | 3.02-3.2 | 3.41 | 0.98-1.22 | 0.1 | 0.1-0.25 |

| M2 | 0.4 | 3.82-4 | 4.32 | 1.28-1.52 | 0.1 | 0.1-0.25 |

| M3 | 0.5 | 5.32-5.5 | 6.01 | 1.88-2.12 | 0.1 | 0.15-0.4 |

| M4 | 0.7 | 6.64-7 | 7.5 | 2.6-3 | 0.2 | 0.15-0.4 |

| M5 | 0.8 | 7.64-7.78 | 8.63 | 3.26-3.74 | 0.2 | 0.15-0.5 |

| M6 | 1 | 9.64-10 | 10.89 | 3.76-4.24 | 0.25 | 0.15-0.5 |

| M8 | 1.25 | 12.57-12.73 | 14.2 | 5.06-5.54 | 0.4 | 0.15-0.6 |

| M10 | 1.5 | 15.57-15.73 | 17.59 | 6.11-6.69 | 0.4 | 0.15-0.6 |

| M12 | 1.75 | 17.57-17.73 | 19.85 | 7.21-7.79 | 0.6 | 0.15-0.6 |

| M14 | 2 | 20.16-21 | 22.78 | 8.51-9.09 | 0.6 | 0.15-0.6 |

| M16 | 2 | 23.16-23.67 | 26.17 | 9.71-10.29 | 0.6 | 0.2-0.8 |

| M18 | 2.5 | 26.15-26.67 | 29.56 | 11.15-11.85 | 0.6 | 0.2-0.8 |

| M20 | 2.5 | 29.16-29.67 | 32.95 | 12.15-12.85 | 0.8 | 0.2-0.8 |

| M22 | 2.5 | 33-34 | 37.29 | 13.65-14.35 | 0.8 | 0.2-0.8 |

| M24 | 3 | 35-36 | 39.55 | 14.65-15.35 | 0.8 | 0.2-0.8 |

| M27 | 3 | 40-41 | 45.2 | 16.65-17.35 | 1 | 0.2-0.8 |

| M30 | 3.5 | 45-46 | 50.85 | 18.28-19.12 | 1 | 0.2-0.8 |

| M33 | 3.5 | 49-50 | 55.37 | 20.58-21.42 | 1 | 0.2-0.8 |

| M36 | 4 | 53.8-55 | 60.79 | 22.08-22.92 | 1 | 0.2-0.8 |

| M39 | 4 | 58.8-60 | 66.44 | 24.58-25.42 | 1 | 0.3-1 |

| M42 | 4.5 | 63.1-65 | 71.3 | 25.58-26.42 | 1.2 | 0.3-1 |

| M45 | 4.5 | 68.1-70 | 76.95 | 27.58-28.42 | 1.2 | 0.3-1 |

| M48 | 5 | 73.1-75 | 82.6 | 29.58-30.42 | 1.6 | 0.3-1 |

| M52 | 5 | 78.1-80 | 88.25 | 32.5-33.5 | 1.6 | 0.3-1 |

The difference between ISO4017 and DIN933:

DIN933 is the German standard, ISO4017 is the international standard, and the EU standard EN ISO 4014. The two are different in the size of the opposite side s and diagonal e of the outer hexagonal head, such as M10, M12, M14M22, and ISO4017 is smaller than DIN933. There is little difference in other specifications. The M10 and M12 are the most commonly used.

How do we control quality of ISO4017 hex bolts?

Controlling the quality of ISO 4017 hex bolts involves implementing comprehensive quality control processes throughout the manufacturing and distribution stages. Here are key aspects of quality control for ISO 4017 hex bolts:

| Control Method | Detail |

|---|---|

| Material Inspection: | Verify the material's composition, heat treatment, and quality upon receipt. Conduct metallurgical analysis to ensure the material properties meet the standards. |

| Process Control: | Implement strict process control measures for heat treatment, machining, threading, and any other manufacturing steps. Maintain consistent process parameters to ensure uniform quality. |

| Inspection Points: | Introduce inspection points at various stages of manufacturing to check for defects, dimensions, and quality. Inspect threading, dimensions, surface finish, and other critical parameters. |

| Sampling and Testing: | Regularly sample products for testing, such as tensile testing, hardness testing, and metallurgical analysis, to ensure they meet the required specifications. |

| Thread Inspection: | Thoroughly inspect threading using proper thread gauges to ensure accurate dimensions and fit with mating components. |

| Traceability: | Implement a traceability system to track each fasteners journey from raw material to final product. This aids in accountability and recalls if necessary. |

Implementing a robust quality management system and conducting regular audits can help ensure consistent adherence to quality standards throughout the production process.

Application of ISO4017 hex bolts:

ISO 4017 hex bolts are part of the ISO metric screw thread series and are used in a variety of applications where reliable and standardized fastening is required. Some common applications include:

| Industry | Details |

|---|---|

| Construction and Building Structures: | ISO 4017 hex bolts are widely used in the construction industry for assembling steel structures, bridges, buildings, and other large-scale projects. They provide secure and durable connections. |

| Machinery and Equipment: | These bolts find applications in the assembly of machinery and equipment across different industries. The standardized metric threads ensure compatibility and interchangeability. |

| Automotive Manufacturing: | ISO 4017 hex bolts are used in the automotive industry for assembling various components in vehicles, including engines, chassis, and other critical parts. |

| Industrial Equipment: | Hex bolts are employed in the assembly of industrial equipment, such as pumps, motors, and manufacturing machinery, where robust fastening is essential. |

| Railroad Infrastructure: | In the construction and maintenance of railroads, ISO 4017 hex bolts are used to secure tracks and related infrastructure components. |

| Power Generation: | Bolts meeting ISO 4017 standards are utilized in power plants for assembling generators, turbines, and other components in the power generation process. |

| Agricultural Machinery: | ISO 4017 hex bolts are applied in the assembly of agricultural machinery and equipment, including tractors and implements. |

| Consumer Goods Manufacturing: | Various products, from appliances to furniture, may use ISO 4017 hex bolts for secure assembly. |

| Renewable Energy Projects: | In the construction of wind turbines and solar installations, hex bolts are used for securing structural components. |

ISO 4017 hex bolts come in various materials and grades, each suited to different environmental conditions and load requirements. Always consider the specific needs of your application and refer to the appropriate standards and specifications for the bolts you are using.

FAQ about ISO4017 hex bolts:

1. What is the pricing for class 8.8 ISO4017 hex bolt?

Generally, our class 8.8 ISO4017 hex bolts are crafted from C45 steel. The pricing comprises materials, processing, packaging, and labor costs. We operate as a bolt manufacturing facility, primarily serving wholesalers and distributors. Our commitment is to ensure the profitability of our customers. The wholesale price range for class 8.8 bolts is approximately 1300-2000 USD per ton. Steel material prices fluctuate frequently, and the price varies based on surface treatment and quantity. For specific pricing, please send inquiries to our email address: Email: info@china-bolts.com

2. What is the typical lead time for delivering a container of bolts?

Our daily production capacity for cold heading and hot forging bolts is approximately 30 tons. However, due to factors such as material preparation, heat treatment, surface treatment, and order scheduling, it requires some time. The average delivery time for a container of bolts is within the range of 30-40 days.

3. Can you assure the quality of these bolts?

Absolutely. From the selection of raw materials to the final packaging, we maintain strict quality control. We understand that there may be concerns regarding the quality of Chinese fasteners. However, we can confidently state that our fasteners meet performance requirements, and we maintain traceable records of the materials used.

4. Are samples available for ISO4017 bolt?

Certainly, we maintain stock of bolts in standard sizes, and we can provide samples free of charge. However, the customer is responsible for covering the freight cost.

5. Is there a minimum order quantity (MOQ) requirement?

Yes, our standard MOQ is approximately one ton. However, for items in our inventory, we can supply even smaller quantities, starting from as low as 10 units.

6. Which countries do you export your bolts to?

Over the course of more than a decade, we have nurtured stable relationships with customers in various countries. These include the United States, Germany, Russia, Poland, Spain, Brazil, Argentina, Vietnam, Canada, Australia, the UAE, Saudi Arabia, and others.