DIN931 Hex Bolts Supplier In China

Ningbo Teng Qi Fasteners Co., Ltd is a din931 hex bolts supplier China. DIN931 is a German standard that specifies the dimensions, mechanical properties, and other relevant requirements for hexagon head bolts with partial threads, commonly known as hex bolts. These bolts typically have a threaded shank with a hexagonal head on one end and a portion of the shank is threaded.

DIN931 hex bolts are used in a variety of applications where a secure and reliable connection is required. The standard covers bolts made from different materials, including steel, stainless steel, and other alloys. It provides specifications for various characteristics such as thread diameter, pitch, length, and mechanical properties like tensile strength and hardness.

These bolts are widely used in construction, machinery, automotive, and other industrial applications. They are particularly useful when a bolt needs to be threaded into a component to a specific depth, while still providing a non-threaded portion for secure fastening.

In summary, DIN931 hex bolts offer a standardized and versatile solution for connecting components in various industries and applications.

Specification:

The DIN 931 is a German standard that specifies partially threaded hexagon head bolts. The specifications include details such as material, thread type, length, head type, and strength class. DIN 931 hex bolts are commonly made from steel or stainless steel, feature metric coarse threads, and are available in various lengths. The hexagon head allows for easy tightening with a wrench or socket. Different strength classes, like 8.8 or 10.9, indicate the bolt’s tensile strength. For precise specifications, it’s advisable to refer to the DIN 931 standard or the manufacturer’s documentation.

The main difference between DIN 931 and DIN 933 hex bolts lies in the threading. DIN 931 specifies partially threaded hexagon head bolts with a portion of the length left unthreaded, suitable for applications requiring a balance of secure fastening and flexibility. On the other hand, DIN 933 specifies fully threaded hexagon head bolts with threads running the entire length, commonly used when complete threading is necessary for the application. The choice between them depends on the specific threading requirements of the intended use.

| Product name | DIN931 Hex Bolts |

|---|---|

| Thread | Metric thread, partially threaded design |

| Thread Diameter | M1.6 – M100 |

| Length | The length of a DIN 931 hex bolt refers to the overall measurement of the bolt, including both the threaded and unthreaded sections. This measurement is from the bottom of the bolt head to the end of the shank. |

| Head Type | Hexagon head, suitable for tightening with a wrench or socket |

| Material | The material for DIN 931 hex bolts can indeed be either steel or stainless steel. |

| Class | Carbon steel: 4.8/6.8/8.8/10.9/12.9 Stainless Steel: A2-70 A2-80 A2-100 A4-70 A4-80 A4-100 |

| Hardness | Class4.8: 130-220HV Class8.8: d≤M16 22-32HRC Class8.8: d>M16 23-34HRC Class10.9: 32-39HRC Class12.9: 39-44HRC |

| Tension Strength | class 4.8: 400Mpa class 8.8: 800Mpa class 10.9: 1000mpa class 12.9: 1200Mpa A2-70: 700Mpa A2-80: 800Mpa A4-70: 700Mpa A4-80: 800Mpa |

| Surface treatment | Black Oxide Coating/Zinc Plating (Electroplating)/Hot-Dip Galvanizing/Mechanical Galvanizing/Dacromet Coating/Painting or Powder Coating |

- RELATED BOLTS LISTS:

- HEX BOLTS

- HEAVY HEX BOLTS

- DIN933 HEX BOLTS

- AS1252 HEX BOLTS

- DIN6914 HEX BOLTS

- ASME B 18.2.1 HEX BOLTS

- A325 HEAVY HEX BOLTS

- A490 HEAVY HEX BOLTS

- RELATED NUTS LIST:

- HEX NUTS

- HEAVY HEX NUTS

- ISO4032 HEX NUTS

- DIN934 HEX NUTS

- A194 HEAVY HEX NUTS

- A563 HEAVY HEX NUTS

- THREADED ROD LIST:

- DIN975 THREADED RODS

- A193 B7 STUD BOLTS

Dimension Chart:

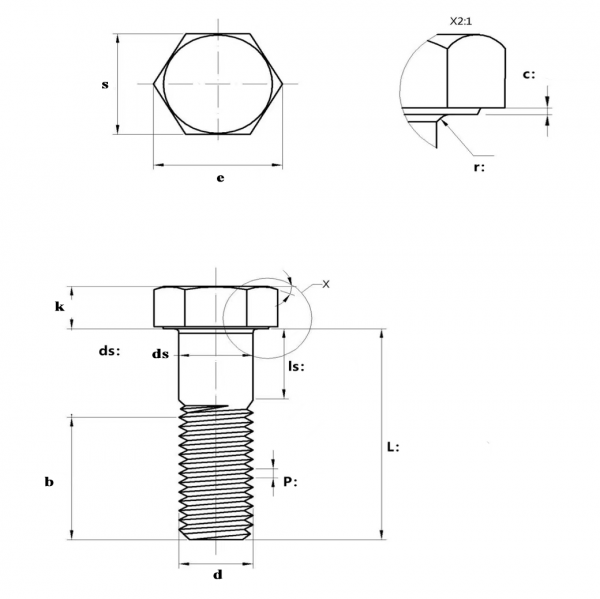

Here’s an explanation of the dimensions included in chart:

1. Thread Size:

– The thread size refers to the diameter and pitch of the threads on the bolt. It is a critical dimension that determines compatibility with nuts and threaded holes.

2. Across Flats (AF) – Hex Head:

– Across flats (AF) is the distance measured from one flat side of the hexagon head to the opposite flat side. It indicates the size of the wrench or socket needed for tightening.

3. Across Corners (AC) – Hex Head:

– Across corners (AC) is the distance measured from one corner of the hexagon head to the opposite corner. It provides an alternative measure for the size of the hex head.

4. Head Thickness – Hex Head:

– The head thickness is the distance measured from the bottom of the hexagon head to the underside of the bolt head. It influences how the bolt fits into recessed or countersunk holes.

5. Rounding Radius (R):

– Rounding radius (R) represents the radius of the curved corners on the hexagon head. It contributes to the overall design, providing a smooth transition from the flat sides to the corners.

By including these dimensions in size chart, we’ve covered key aspects of the hex bolt’s geometry, ensuring that users have comprehensive information for selecting and using the bolts effectively in various applications.

| Thread Diameter(d) | Thread Pitch(P) | Width Across Flat (s) | Width Across Corner(e) Min | Head Height (k) | Radius(r) Min | Washer Face Thickness(c) | Thread Length(b) L≤125 | Thread Length(b) 125<L≤200 | Thread Length(b) L>200 |

| M1.6 | 0.35 | 3.02-3.2 | 3.41 | 0.98-1.22 | 0.1 | 0.1-0.25 | 9 | - | - |

| M2 | 0.4 | 3.82-4 | 4.32 | 1.28-1.52 | 0.1 | 0.1-0.25 | 10 | - | - |

| M3 | 0.5 | 5.32-5.5 | 6.01 | 1.88-2.12 | 0.1 | 0.15-0.4 | 12 | - | - |

| M4 | 0.7 | 6.64-7 | 7.5 | 2.6-3 | 0.2 | 0.15-0.4 | 14 | - | - |

| M5 | 0.8 | 7.64-7.78 | 8.63 | 3.26-3.74 | 0.2 | 0.15-0.5 | 16 | 22 | - |

| M6 | 1 | 9.64-10 | 10.89 | 3.76-4.24 | 0.25 | 0.15-0.5 | 18 | 24 | - |

| M8 | 1.25 | 12.57-12.73 | 14.2 | 5.06-5.54 | 0.4 | 0.15-0.6 | 22 | 28 | - |

| M10 | 1.5 | 16.57-16.73 | 18.72 | 6.11-6.69 | 0.4 | 0.15-0.6 | 26 | 32 | 45 |

| M12 | 1.75 | 18.48-19 | 20.88 | 7.21-7.79 | 0.6 | 0.15-0.6 | 30 | 36 | 49 |

| M14 | 2 | 21.16-21.67 | 23.91 | 8.51-9.09 | 0.6 | 0.15-0.6 | 34 | 40 | 53 |

| M16 | 2 | 23.16-23.67 | 26.17 | 9.71-10.29 | 0.6 | 0.2-0.8 | 38 | 44 | 57 |

| M18 | 2.5 | 26.15-26.67 | 29.56 | 11.15-11.85 | 0.6 | 0.2-0.8 | 42 | 48 | 61 |

| M20 | 2.5 | 29.16-29.67 | 32.95 | 12.15-12.85 | 0.8 | 0.2-0.8 | 46 | 52 | 65 |

| M22 | 2.5 | 31-32 | 35.03 | 13.65-14.35 | 0.8 | 0.2-0.8 | 50 | 56 | 69 |

| M24 | 3 | 35-36 | 39.55 | 14.65-15.35 | 0.8 | 0.2-0.8 | 54 | 60 | 73 |

| M27 | 3 | 40-41 | 45.2 | 16.65-17.35 | 1 | 0.2-0.8 | 60 | 66 | 79 |

| M30 | 3.5 | 45-46 | 50.85 | 18.28-19.12 | 1 | 0.2-0.8 | 66 | 72 | 85 |

| M33 | 3.5 | 49-50 | 55.37 | 20.58-21.42 | 1 | 0.2-0.8 | 72 | 78 | 91 |

| M36 | 4 | 53.8-55 | 60.79 | 22.08-22.92 | 1 | 0.2-0.8 | 78 | 84 | 97 |

| M39 | 4 | 58.8-60 | 66.44 | 24.58-25.42 | 1 | 0.3-1 | 84 | 90 | 103 |

| M42 | 4.5 | 63.1-65 | 71.3 | 25.58-26.42 | 1.2 | 0.3-1 | 90 | 96 | 109 |

| M45 | 4.5 | 68.1-70 | 76.95 | 27.58-28.42 | 1.2 | 0.3-1 | 96 | 102 | 115 |

| M48 | 5 | 73.1-75 | 82.6 | 29.58-30.42 | 1.6 | 0.3-1 | 102 | 108 | 121 |

| M52 | 5 | 78.1-80 | 88.25 | 32.5-33.5 | 1.6 | 0.3-1 | - | 116 | 129 |

| M56 | 5.5 | 82.8-85 | 93.56 | 34.5-35.5 | 2 | 1 max | - | 124 | 137 |

| M64 | 6 | 92.8-95 | 104.86 | 39.5-40.5 | 2 | 1 max | - | 132 | 145 |

| M72 | 6 | 102.8-105 | 116.16 | 44.5-45.5 | 2 | 1 max | - | 156 | 169 |

Application of DIN931 Bolt:

DIN 931 hex bolts are versatile and find applications across various industries due to their strength. Some common uses include:

| Industry | Details |

|---|---|

| Construction: | Fastening steel beams, columns, and components with DIN 931 hex bolts is common in structural applications. |

| Machinery: | DIN 931 hex bolts secure machine parts in manufacturing and industrial machinery assembly. |

| Automotive: | In vehicle assembly, DIN 931 hex bolts are used to secure engine components, chassis, and other parts. |

| Infrastructure Projects: | DIN 931 hex bolts play a role in the construction of bridges, roads, and other infrastructure projects, securing structural elements. |

| Renewable Energy: | Wind turbines, solar panel structures, and other components in the renewable energy sector often use DIN 931 hex bolts. |

| Railway: | Fastening railway tracks and related infrastructure components with DIN 931 hex bolts is standard. |

| Marine: | Shipbuilding and marine structures utilize DIN 931 hex bolts for joining and securing various components. |

| Electronics: | DIN 931 hex bolts are part of the assembly process for electronic equipment and cabinets. |

| Agriculture: | Agricultural machinery and equipment use DIN 931 hex bolts for fastening and securing various parts. |

FAQ about DIN931 hex bolts manufacturer:

1.What materials are commonly used in manufacturing DIN 931 hex bolt?

DIN931 hex bolts are often manufactured from materials such as steel, stainless steel, brass, and other alloys, depending on the application’s requirements.

2.Can you produce custom DIN931 hex bolts to meet specific requirements?

Yes, we can customize DIN931 hex bolt with specific lengths, materials, coatings, or other features to meet unique customer needs.

3.What quality control measures are in place during DIN931 hex bolt manufacturing?

Quality control involves dimensional checks, thread quality inspections, material testing, and surface finish evaluations to ensure the bolts meet DIN standards and customer specifications.

4.How can you ensure the consistency of DIN 931 hex bolt quality in large-scale production?

Now our DIN931 bolts smaller than M24 are automatic cold heading and automatic wire rolling. Automation is crucial for improving efficiency, precision, and quality control in large-scale DIN 931 hex bolt production.

5. What are the factors that influence the cost of manufacturing DIN931 hex bolts?

Factors include material choice, size, quantity, customizations, and additional processes like coatings, which can impact the overall cost.

6.Do you have price advantage for DIN931 hex bolts?

Yes. We are truly a large-scale bolt factory with absolute price and quality advantage in the world.