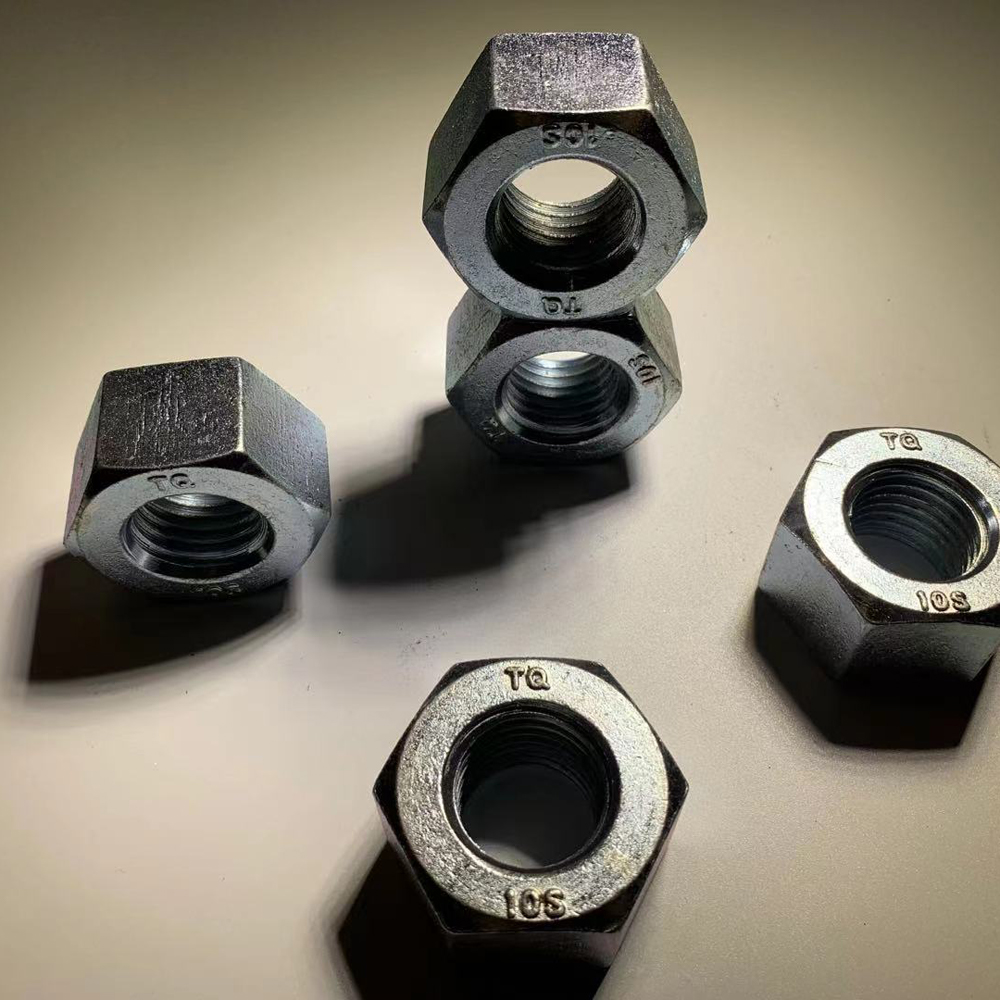

Heavy Hex Nuts Supplier In China

Heavy hex nuts are a type of nut that feature a larger and thicker hexagonal shape compared to standard hex nuts. These nuts are designed to provide a larger bearing surface and enhanced load distribution when used in conjunction with heavy hex bolts or large-diameter bolts. They are commonly used in applications where secure and stable connections are essential, particularly in construction, structural engineering, and industrial settings.

Standard of Heavy Hex Nut:

Specification of Heavy Hex Nuts:

| Production method: | Nut shall be cold formed, warm formed, hot formed, hot forged, machined |

| Bearing Surface | The larger size of heavy hex nuts results in a larger bearing surface compared to standard hex nuts. This larger surface area distributes the load over a wider area, reducing the risk of material deformation or damage. |

| Thread Specifications: | Heavy hex nuts are manufactured from various materials, including carbon steel, alloy steel, and stainless steel. Material selection depends on factors such as strength requirements and corrosion resistance. |

| Material: | Heavy hex nuts are manufactured from various materials, including carbon steel, alloy steel, and stainless steel. Material selection depends on factors such as strength requirements and corrosion resistance. |

| Heat treatment requirements: | The bolts are subjected to heat treatment processes such as quenching and tempering to achieve the desired mechanical properties, including hardness and tensile strength. |

| Strength Grade: | Heavy hex nuts are available in different strength grades to match the strength of the bolts they are paired with. This ensures compatibility and consistent load-bearing capacity. |

| Markings and Identification: | Heavy hex nuts are typically marked with specific codes and symbols that provide information about their specifications. |

| Standards and Specifications: | Heavy hex nuts are manufactured in accordance with industry standards, such as those set by organizations like ASTM (American Society for Testing and Materials). |

Application:

Heavy hex nuts are used in a variety of applications across different industries where secure and reliable connections are essential. Here are some prominent application areas for heavy hex nuts:

| Construction and Structural Engineering: | Nut shall be cold formed, warm formed, hot formed, hot forged, machinedHeavy hex nuts are commonly used in construction projects for fastening structural components such as beams, columns, and trusses. - They play a crucial role in providing stability and load-bearing capacity in buildings, bridges, and other structures. |

| Infrastructure Projects: | In transportation infrastructure, heavy hex nuts secure components like rails, track systems, and signaling equipment in railroads and subway systems. - Heavy hex nuts are used in highway construction for guardrails, signposts, and road barriers. |

| Industrial Machinery and Equipment: | Heavy hex nuts are employed in the assembly of heavy machinery and equipment used in manufacturing, mining, and other industrial sectors. - They secure components like motors, gears, and mechanical systems in place. |

| Power Generation: | Heavy hex nuts are used in power plants to secure equipment such as turbines, generators, and cooling systems. - In renewable energy installations, heavy hex nuts are used in wind turbines and solar panel mounting systems. |

| Oil and Gas Industry: | In offshore drilling rigs and platforms, heavy hex nuts secure critical equipment and structural components against harsh marine conditions. |

| Transportation Equipment: | Heavy hex nuts are used in the assembly of trucks, buses, and heavy vehicles to secure chassis components and other structural elements. |

| Aerospace and Defense: | Heavy hex nuts find application in aerospace engineering, securing components of aircraft and spacecraft. |

| Marine Industry: | In shipbuilding, heavy hex nuts are used to fasten structural elements and machinery components in vessels. |

| Water and Wastewater Treatment: | Heavy hex nuts secure pipes, valves, and components in water treatment plants, ensuring the reliable functioning of the infrastructure. |

| Industrial Piping: | In various industrial applications, heavy hex nuts secure pipes and fittings, maintaining the integrity of fluid and gas transportation systems. |

These are just a few examples of the diverse applications of heavy hex nuts. Their ability to provide secure and durable connections makes them indispensable components in industries that rely on strong, stable, and reliable fastening solutions.

Surface treatment of heavy hex nut:

| Surface treament | Feature | Benefits |

|---|---|---|

| Black Oxide Coating | Creates a dark or black surface finish through a chemical reaction. | Enhances appearance, provides some corrosion resistance, reduces glare, and can offer moderate wear resistance. |

| Zinc Plating (Electroplating) | Provides a thin layer of zinc coating on the surface. | Offers moderate corrosion resistance, enhances appearance, and can act as a sacrificial barrier against corrosion. |

| Hot-Dip Galvanizing | Immerses the bolts and nuts in molten zinc to create a thicker coating. | Provides strong corrosion protection, suitable for outdoor and harsh environments, forms a durable and rugged coating. |

| Mechanical Galvanizing | Uses mechanical means to apply a zinc coating. | Offers good corrosion protection, especially for high-strength bolts, less risk of hydrogen embrittlement compared to hot-dip galvanizing. |

| Dacromet Coating | A sacrificial coating that includes a mix of zinc and aluminum flakes. | Offers exceptional corrosion resistance, suitable for extreme conditions, provides consistent friction control, and maintains coating integrity even under mechanical stress. |

Heavy Hex Nut Wholesale Price (blackening oxidation):

| Norminal Size | Thread Per Inch | MOQ | USD Price/1000pc | Weight/1000pcs |

|---|---|---|---|---|

| 1/4″ | 20 | 200000 | 10.5 | 5.3 |

| 5/16″ | 18 | 130000 | 15 | 7.82 |

| 3/8″ | 16 | 70000 | 27 | 14.3 |

| 7/16″ | 14 | 53000 | 36 | 18.9 |

| 1/2″ | 13 | 33700 | 56 | 29.7 |

| 9/16″ | 12 | 27000 | 70 | 37 |

| 5/8″ | 11 | 18500 | 103 | 54 |

| 3/4″ | 10 | 11500 | 168 | 87.5 |

| 7/8″ | 9 | 7500 | 258 | 134.7 |

| 1″ | 8 | 5200 | 368 | 192.8 |

| 1 1/8″ | 8 | 3700 | 515 | 268.5 |

| 1 1/4″ | 8 | 2800 | 682 | 356.5 |

| 1 3/8″ | 8 | 2200 | 885 | 462.7 |

| 1 1/2″ | 8 | 1700 | 1135 | 594.2 |

-

- The above is only a partial size price for reference. The price of steel fluctuates frequently. Please contact us for more specific price.

How do we ensure the quality of heavy hex nut?

In a world where connections matter, Ningbo Teng Qi Fasteners is more than just a hex nuts supplier and manufacturer. We are architects of stability, builders of relationships, and champions of your success. From skyscrapers that reach for the sky to machines that power industries, our hex bolts form the backbone of progress. When you choose Ningbo Teng Qi Fasteners, you choose unwavering quality, exceptional service, and a partner who understands that every bolt holds a piece of your vision.

| Control Method | Detail |

|---|---|

| Material Inspection: | Verify the material's composition, heat treatment, and quality upon receipt. Conduct metallurgical analysis to ensure the material properties meet the standards. |

| Process Control: | Implement strict process control measures for heat treatment, machining, threading, and any other manufacturing steps. Maintain consistent process parameters to ensure uniform quality. |

| Inspection Points: | Introduce inspection points at various stages of manufacturing to check for defects, dimensions, and quality. Inspect threading, dimensions, surface finish, and other critical parameters. |

| Sampling and Testing: | Regularly sample products for testing, such as tensile testing, hardness testing, and metallurgical analysis, to ensure they meet the required specifications. |

| Thread Inspection: | Thoroughly inspect threading using proper thread gauges to ensure accurate dimensions and fit with mating components. |

| Traceability: | Implement a traceability system to track each fasteners journey from raw material to final product. This aids in accountability and recalls if necessary. |