DIN933 Hex Bolts Supplier Exporter in China

Ningbo Teng Qi Fasteners Co.,Ltd is a supplier of DIN933 hex bolts in China. DIN933 standard specifies requirements for M1,6 to M 52 hexagon head screws threaded up to the head, bolts can be blackened, phosphated, galvanized, Dacromet, cadmium plated, chrome plated, nickel-chromium alloy plated, hot-dip galvanized, Teflon and other surface treatments according to customer requirements. Widely used in electrical appliances, automobiles, Bridges, high-speed railways, aviation, construction, power, energy, steel structure, construction machinery and other fields.

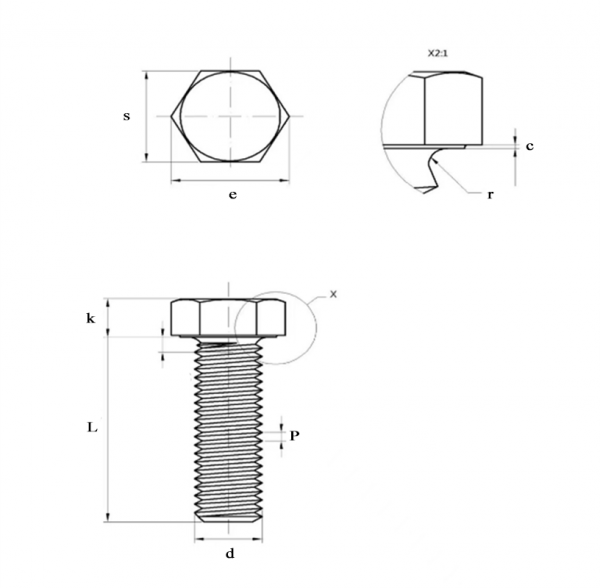

Specification of DIN933 Hex Bolts:

The specifications for DIN 933 hex bolts, which are defined by the Deutsches Institut für Normung (DIN), cover various aspects including dimensions, materials, and tolerances. Here’s a general overview of the specifications for DIN 933 hex bolts:

| Product name | DIN933 Hex Bolts |

|---|---|

| Thread | Full threads run along the entire length of the bolt, providing a secure and stable fastening. |

| Size | The standard is based on metric dimensions, and the sizing is expressed in millimeters. This includes specifications for both the diameter and length of the bolts. |

| Head Type | Hexagonal head with six flat sides, designed for easy tightening with a wrench or socket. |

| Hardness | Class4.8: 130-220HV Class8.8: d≤M16 22-32HRC Class8.8: d>M16 23-34HRC Class10.9: 32-39HRC Class12.9: 39-44HRC |

| Class | Class4.8/8.8/10.9/12.9 A2-70 A2-80 A4-70 A4-80 A4-100 |

| Material | The DIN standard allows for the manufacture of these hex bolts using various materials, including but not limited to: - Carbon steel - Alloy steel - Stainless steel |

| Surface treatment | The standard specifies surface finishes to enhance corrosion resistance and appearance. Common finishes include: - Plain (uncoated) - Zinc plating - Hot-dip galvanizing - Other corrosion-resistant coatings |

- RELATED BOLTS LISTS:

- HEX BOLTS

- HEAVY HEX BOLTS

- DIN931 HEX BOLTS

- AS1252 HEX BOLTS

- DIN6914 HEX BOLTS

- ASME B 18.2.1 HEX BOLTS

- A307 HEX BOLTS

- A394 HEX BOLTS

- ASTM A354 HEX BOLTS

- A325 HEAVY HEX BOLTS

- A490 HEAVY HEX BOLTS

- RELATED NUTS LIST:

- HEX NUTS

- HEAVY HEX NUTS

- ISO4032 HEX NUTS

- DIN934 HEX NUTS

- A194 HEAVY HEX NUTS

- A563 HEAVY HEX NUTS

- THREADED ROD LIST:

- DIN975 THREADED RODS

- A193 B7 STUD BOLTS

Dimension Chart:

Here’s an explanation of the dimensions included in chart:

1. Thread Size:

– The thread size refers to the diameter and pitch of the threads on the bolt. It is a critical dimension that determines compatibility with nuts and threaded holes.

2. Across Flats (AF) – Hex Head:

– Across flats (AF) is the distance measured from one flat side of the hexagon head to the opposite flat side. It indicates the size of the wrench or socket needed for tightening.

3. Across Corners (AC) – Hex Head:

– Across corners (AC) is the distance measured from one corner of the hexagon head to the opposite corner. It provides an alternative measure for the size of the hex head.

4. Head Thickness – Hex Head:

– The head thickness is the distance measured from the bottom of the hexagon head to the underside of the bolt head. It influences how the bolt fits into recessed or countersunk holes.

5. Rounding Radius (R):

– Rounding radius (R) represents the radius of the curved corners on the hexagon head. It contributes to the overall design, providing a smooth transition from the flat sides to the corners.

By including these dimensions in size chart, we’ve covered key aspects of the hex bolt’s geometry, ensuring that users have comprehensive information for selecting and using the bolts effectively in various applications.

| Thread Diameter(d) | Thread Pitch(P) | Width Across Flat (s) | Width Across Corner(e) Min | Head Height (k) | Radius(r) Min | Washer Face Thickness(c) |

| M1.6 | 0.35 | 3.02-3.2 | 3.41 | 0.98-1.22 | 0.1 | 0.1-0.25 |

| M2 | 0.4 | 3.82-4 | 4.32 | 1.28-1.52 | 0.1 | 0.1-0.25 |

| M3 | 0.5 | 5.32-5.5 | 6.01 | 1.88-2.12 | 0.1 | 0.15-0.4 |

| M4 | 0.7 | 6.64-7 | 7.5 | 2.6-3 | 0.2 | 0.15-0.4 |

| M5 | 0.8 | 7.64-7.78 | 8.63 | 3.26-3.74 | 0.2 | 0.15-0.5 |

| M6 | 1 | 9.64-10 | 10.89 | 3.76-4.24 | 0.25 | 0.15-0.5 |

| M8 | 1.25 | 12.57-12.73 | 14.2 | 5.06-5.54 | 0.4 | 0.15-0.6 |

| M10 | 1.5 | 16.57-16.73 | 18.72 | 6.11-6.69 | 0.4 | 0.15-0.6 |

| M12 | 1.75 | 18.48-19 | 20.88 | 7.21-7.79 | 0.6 | 0.15-0.6 |

| M14 | 2 | 21.16-21.67 | 23.91 | 8.51-9.09 | 0.6 | 0.15-0.6 |

| M16 | 2 | 23.16-23.67 | 26.17 | 9.71-10.29 | 0.6 | 0.2-0.8 |

| M18 | 2.5 | 26.15-26.67 | 29.56 | 11.15-11.85 | 0.6 | 0.2-0.8 |

| M20 | 2.5 | 29.16-29.67 | 32.95 | 12.15-12.85 | 0.8 | 0.2-0.8 |

| M22 | 2.5 | 31-32 | 35.03 | 13.65-14.35 | 0.8 | 0.2-0.8 |

| M24 | 3 | 35-36 | 39.55 | 14.65-15.35 | 0.8 | 0.2-0.8 |

| M27 | 3 | 40-41 | 45.2 | 16.65-17.35 | 1 | 0.2-0.8 |

| M30 | 3.5 | 45-46 | 50.85 | 18.28-19.12 | 1 | 0.2-0.8 |

| M33 | 3.5 | 49-50 | 55.37 | 20.58-21.42 | 1 | 0.2-0.8 |

| M36 | 4 | 53.8-55 | 60.79 | 22.08-22.92 | 1 | 0.2-0.8 |

| M39 | 4 | 58.8-60 | 66.44 | 24.58-25.42 | 1 | 0.3-1 |

| M42 | 4.5 | 63.1-65 | 71.3 | 25.58-26.42 | 1.2 | 0.3-1 |

| M45 | 4.5 | 68.1-70 | 76.95 | 27.58-28.42 | 1.2 | 0.3-1 |

| M48 | 5 | 73.1-75 | 82.6 | 29.58-30.42 | 1.6 | 0.3-1 |

| M52 | 5 | 78.1-80 | 88.25 | 32.5-33.5 | 1.6 | 0.3-1 |

Comparison din933 hex bolts with din931 hex bolts:

DIN 933 and DIN 931 are both standards for metric hex bolts. The main difference lies in their lengths:

DIN 933 specifies hex bolts with full thread, meaning the thread extends the entire length of the bolt.

DIN 931 specifies hex bolts with partial thread, where only a portion of the bolt has threading, leaving an unthreaded shank.

When choosing between DIN 933 and DIN 931 hex bolts, consider your application requirements regarding threading and the mechanical properties needed for the specific task.

Manufacturing Process:

The manufacturing process of DIN933 hex bolts typically involves the following steps:

| Production Procession of Hex Bolts |

|---|

| 1. Material Preparation: - Round wire steel undergoes phosphating and wire drawing to required dimension. This step ensures that the material is appropriately sized for the subsequent forming process. |

| 2. Forming: Size smaller M24 or 1": Cold heading -Feed the cut material into a cold heading machine, which uses punches and dies to shape the material at room temperature. The machine compresses the material, forming it into the desired hexagonal shape for the bolt head. Size Larger than M24 or 1": Hot Forging - This process involves heating the material to a high temperature and shaping it using dies or molds. In the context of hex bolts, hot forging imparts the desired hexagonal shape to the head of the bolt. |

| 3. Thread rolling: - Use a thread rolling machine for thread rolling. Product is placed between two rollers and enough pressure is applied to cause the material to thread between the rollers. |

| 4. Heat Treatment: - Heat treatment is applied to improve the hardness and strength of the hex bolts. |

| 5. Surface Treatment: - The final step involves surface treatment, enhancing corrosion resistance and providing a polished finish. |

Quality Control:

The quality control of DIN 933 hex bolts involves a systematic process to ensure that the manufactured bolts meet specified standards and adhere to required quality criteria. Here are key aspects of the quality control process for DIN 933 hex bolts:

| Control Method | Detail |

|---|---|

| Material Inspection: | Verify the material's composition, heat treatment, and quality upon receipt. Conduct metallurgical analysis to ensure the material properties meet the standards. |

| Process Control: | Implement strict process control measures for heat treatment, machining, threading, and any other manufacturing steps. Maintain consistent process parameters to ensure uniform quality. |

| Inspection Points: | Introduce inspection points at various stages of manufacturing to check for defects, dimensions, and quality. Inspect threading, dimensions, surface finish, and other critical parameters. |

| Sampling and Testing: | Regularly sample products for testing, such as tensile testing, hardness testing, and metallurgical analysis, to ensure they meet the required specifications. |

| Thread Inspection: | Thoroughly inspect threading using proper thread gauges to ensure accurate dimensions and fit with mating components. |

| Traceability: | Implement a traceability system to track each fasteners journey from raw material to final product. This aids in accountability and recalls if necessary. |

Application of DIN933 hex bolt:

DIN 933 hex bolts find applications in a wide range of industries and scenarios where a robust and reliable fastening solution is required. Here are some common applications:

| Industry | Details |

|---|---|

| Construction: | DIN 933 hex bolts are frequently used in the construction industry for assembling structural components. Their strength and stability make them suitable for connecting beams, columns, and other load-bearing elements. |

| Machinery: | In machinery and equipment manufacturing, hex bolts are utilized for joining different machine components securely. They play a crucial role in maintaining the structural integrity and functionality of machines. |

| Automotive: | DIN 933 hex bolts are employed in the automotive sector for assembling various components of vehicles. They are used in engine parts, chassis, and other critical areas where secure fastening is essential. |

| Electrical Equipment: | These hex bolts are used in the assembly of electrical panels, control boxes, and other electrical equipment. Their durability and resistance to vibration make them suitable for securing components in these applications. |

| Railroad Industry: | They play a vital role in infrastructure projects, such as bridges, highways, and railways, where strong and reliable connections are essential. |

| Electrical and Electronics: | DIN 933 hex bolts are utilized in the construction and maintenance of railroad tracks and structures. They provide a secure fastening method for rail components. |

| Aerospace: | In aerospace applications, where precision and reliability are paramount, hex bolts are employed for fastening components in aircraft construction and maintenance. |

| Marine and Shipbuilding: | The corrosion-resistant properties of certain materials used for DIN 933 hex bolts make them suitable for marine environments. They are employed in shipbuilding and other maritime applications. |

| Heavy Equipment: | Industries involving heavy equipment, such as mining and agriculture, use hex bolts for assembling and maintaining machinery due to their robust construction. |

| Infrastructure: | DIN 933 hex bolts are used in the construction and maintenance of various infrastructure projects, including bridges, tunnels, and utility structures. |

FAQ about DIN933 hex bolt:

1.What’s the price of class 8.8 din933 hex bolts?

In general, our class 8.8 din933 hex bolts are made of c45 steel. The price is made up of materials, processing, packaging and labor costs. We are focused on the production of bolts factory, the main customers are for wholesalers, distributors. Committed to making our customers profitable. The wholesale price of 8.8 class bolts is 1300-2000usd/ton. The material price of steel will fluctuate frequently, and the price is different for different surface treatment/quantity, so please send the inquiry to our email for the specific price. Emai: info@china-bolts.com

2.How many days does it take you to deliver a container of bolts?

Our daily production capacity of cold heading and hot forging bolts is about 30 tons, but due to the arrangement of materials, heat treatment, surface treatment, order scheduling takes time. The average delivery time of bolts for a container is 30-40 days.

3.Can you guarantee the quality of the bolts?

Yes. From raw materials to final packaging, we strictly control quality. Many enterprises have a bias against the quality of Chinese fasteners, we can ensure that the fasteners manufactured by us meet the performance requirements and the materials are traceable.

4.Can you provide samples of DIN933 bolts?

Yes, we have some stock in regular sizes. Samples can be provided free of charge. But the customer needs to bear the freight.

5. Do you have a minimum order quantity requirement?

Yes, the MOQ we usually produce is about one ton. But we have most sizes in stock, so for inventory items, even 10 units we can supply.

6.What countries do you export your bolts to?

We have stable customers in the United States, Germany, Russia, Poland, Spain, Brazil, Argentina, Vietnam, Canada, Australia, UAE, Saudi Arabia and other countries for more than 10 years.