AS 1112.1 Australian Standard Metric Hex Nut Manufacturer In China

Ningbo Teng Qi Fasteners is a manufacturer specializing in the production of high-quality Australian Standard AS1112.1 hex nuts, we are committed to providing customers with reliable products and excellent services. Our products come in a wide range of sizes, from M1.6 to M64, to meet the needs of a variety of industries and applications.

We have advanced production equipment, including cold heading machines, tapping machines, chamfering machines, hot forging machines, etc., as well as professional testing equipment, such as load holding test, thread pass and stop gauge test, metallographic analysis after heat treatment, etc. Through strict production processes and quality control, we ensure that every nut meets high standards of quality requirements.

Product quality is the core competitiveness of our factory. We pay attention to every detail, from the selection of raw materials to the monitoring of the production process, to ensure that the performance and reliability of the products meet standard requirements. Our nuts undergo strict quality inspection and comply with AS1112.1 standards as well as international quality certification requirements. Our products not only enjoy a good reputation in the domestic market, but are also exported to many countries and regions such as Australia, the United States, and Europe.

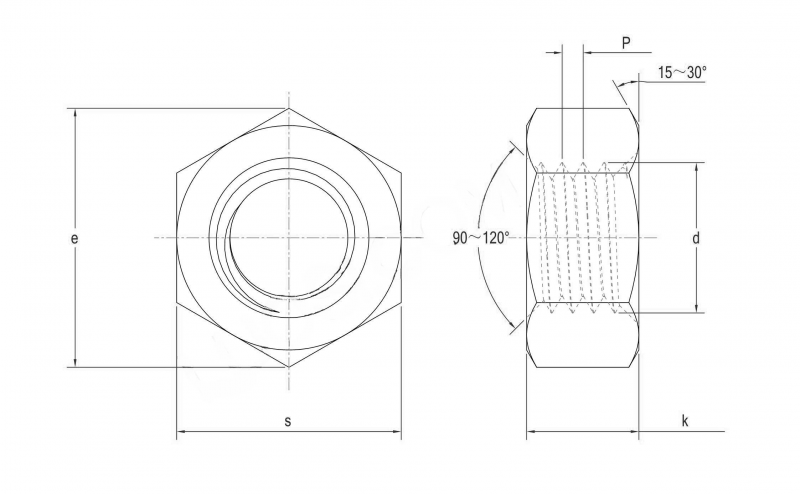

Specification of AS 1112.1 Metric Hex Nut:

The specification of AS 1112.1 Metric Hex Nut include the following details:

| Application | Details |

|---|---|

| Construction Industry: | These nuts are widely used in construction projects for fastening structural components such as beams, columns, and trusses. They ensure the stability and integrity of the structures by securely holding the components together. |

| Machinery and Equipment: | AS1112.1 hex nuts are employed in the assembly of heavy machinery and equipment. They provide a reliable means of fastening components in place, ensuring operational safety and efficiency. |

| Automotive and Transportation: | Hex coupling nuts find applications in the automotive and transportation industries for connecting various components, including suspension systems, exhaust systems, and engine mounts. They provide a secure connection while allowing for flexibility and adjustment in vehicle assemblies. |

| Power Generation: | In power generation facilities such as thermal power plants and wind farms, AS1112.1 hex nuts are used in the assembly of turbines, generators, and other equipment. They provide secure fastening solutions for critical components in these facilities. |

| Marine and Offshore Applications: | AS1112.1 hex nuts are also used in marine and offshore industries for securing components in shipbuilding, offshore platforms, and marine structures. Their corrosion-resistant properties make them suitable for use in harsh marine environments. |

Dimension Chart of Australian Standard AS 1112.1 Metric Hex Nut:

| Thread Diameter | M1.6 | M2 | M2.5 | M3 | M3.5 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 |

| P | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

| e min | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 14.38 | 17.77 | 20.03 | 23.36 | 26.75 | 29.56 | 32.95 | 37.29 | 39.55 |

| k max | 1.3 | 1.6 | 2 | 2.4 | 2.8 | 3.2 | 4.7 | 5.2 | 6.8 | 8.4 | 10.8 | 12.8 | 14.8 | 15.8 | 18 | 19.4 | 21.5 |

| k min | 1.05 | 1.35 | 1.75 | 2.15 | 2.55 | 2.9 | 4.4 | 4.9 | 6.44 | 8.04 | 10.37 | 12.1 | 14.1 | 15.1 | 16.9 | 18.1 | 20.2 |

| s max | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 30 | 34 | 36 |

| s min | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.16 | 29.16 | 33 | 35 |

| Thread Diameter | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | M52 | M56 | M60 | M64 | |

| P | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 | |

| e min | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 | |

| k max | 15.8 | 18 | 19.4 | 21.5 | 23.8 | 25.6 | 28.7 | 31 | 33.4 | 34 | 36 | 38 | 42 | 45 | 48 | 51 | |

| k min | 15.1 | 16.9 | 18.1 | 20.2 | 22.5 | 24.3 | 27.4 | 29.4 | 31.8 | 32.4 | 34.4 | 36.4 | 40.4 | 43.4 | 46.4 | 49.1 | |

| s max | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | 95 | |

| s min | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 | |

- RELATED NUT LISTS:

- DIN6334 Hexagon Coupling Nuts

- ASME/ANSI B 18.2.2 Hex Slotted Nuts/Castle Nuts

- ASME/ANSI B18.2.2 Hex Flange Nuts

- Lock Nuts

- IFI145 Flange Nuts

- DIN982 Nylon Lock Nuts

- DIN985 Nylon Lock Nuts

- ASME B 18.16.6 Nylon Nuts

- HEX NUT

- JIS 1186 Hex Nuts

- DIN934 Hex Nuts

- A194 Hex Nuts

- A563 Hex Nuts

- DIN6915 Hex Nuts

- GOST 28919 Thick Hex Nuts

- GOST R 52645 Structural Hex Nuts

- GOST 5915 Hex Nut

- UNI5588 Hex Nuts

- UNI5587 Thick Hex Nuts

- UNI5713 Hex Nuts

- AS1252 Hex Nuts

- AS/NZS 2451 Hex Nuts

- AS/NZS 2465 Hex Nuts

- DIN6330 Hex Thick Nuts

- ASME/ANSI B 18.2.2 Hex Thick Nuts

Application of AS 1112.1 Metric Hex Nut:

DIN 6334 hex coupling nuts are versatile fasteners with a threaded hole in the center, designed to connect two threaded rods or studs. Their unique design and functionality make them suitable for various applications across different industries.

Our products are widely used in construction, machinery manufacturing, automobile industry, electronic equipment and other fields. Whether connecting structural members, mechanical equipment or automotive components, our products ensure strong and reliable connections, providing reliable support for our customers’ projects and businesses.

We are committed to continuously improving product quality and service levels, always taking customer satisfaction as our ultimate goal. If you are interested in our products or have any needs, please feel free to contact us. We look forward to establishing a long-term cooperative relationship with you and providing support and assistance for your business development.

| Application | Details |

|---|---|

| Construction Industry: | These nuts are widely used in construction projects for fastening structural components such as beams, columns, and trusses. They ensure the stability and integrity of the structures by securely holding the components together. |

| Machinery and Equipment: | AS1112.1 hex nuts are employed in the assembly of heavy machinery and equipment. They provide a reliable means of fastening components in place, ensuring operational safety and efficiency. |

| Automotive and Transportation: | Hex coupling nuts find applications in the automotive and transportation industries for connecting various components, including suspension systems, exhaust systems, and engine mounts. They provide a secure connection while allowing for flexibility and adjustment in vehicle assemblies. |

| Power Generation: | In power generation facilities such as thermal power plants and wind farms, AS1112.1 hex nuts are used in the assembly of turbines, generators, and other equipment. They provide secure fastening solutions for critical components in these facilities. |

| Marine and Offshore Applications: | AS1112.1 hex nuts are also used in marine and offshore industries for securing components in shipbuilding, offshore platforms, and marine structures. Their corrosion-resistant properties make them suitable for use in harsh marine environments. |