DIN915 Dog Point Hexagon Socket Set Screws Supplier Exporter In China

Ningbo Teng Qi Fasteners Co., Ltd is a supplier of DIN 915 set screws in China. With a steadfast commitment to strict quality control and the use of high-quality materials, we deliver DIN 915 set screws that meet industry standards, offering reliability and durability for diverse applications.

Elevate your fastening solutions with our precision-engineered DIN 915 set screws. By partnering with us, you gain access to unmatched industry expertise, unwavering quality control, and a dedication to using premium materials. Choose Ningbo Teng Qi Fasteners Co., Ltd as your go-to manufacturer for DIN 915 set screws, setting new benchmarks in reliability and performance.

Specification:

The DIN 915 set screw is a standardized fastener designed with a dog point, following the specifications of the Deutsches Institut für Normung (DIN). This screw typically features a threaded body, is made from materials like steel or stainless steel, and includes an internal hex socket drive for installation. The distinctive dog point serves the purpose of facilitating alignment and positioning in various applications, providing a reference point.

| Product Name: | DIN915 Set Screw |

| Diameter | Diameter: The diameter of a DIN 915 set screw refers to the measurement across the widest point of the screw’s threaded portion. It is typically specified using the metric system, ranging from M3 to M24. The diameter determines the size of the threaded hole into which the set screw will be inserted and tightened. |

| Length | Length: The length of a DIN 915 set screw indicates how far it extends when fully threaded into a mating component or surface. Lengths can vary depending on the specific application and requirements, ranging from a few millimeters to several tens of millimeters. The length specification is essential for ensuring proper engagement and secure fastening of components. |

| Class | Steel: 45H Stainless Steel;A2-70,A4,C3,A2-50 |

| Type | Hexagon socket set screw with a dog point |

| Material | High-strength steel (e.g., SCM435) Alloy steel (e.g., ML40CR) Medium to low-carbon steel Copper Aluminum Stainless steel |

| Manufacturing Process | wire drawing, cold heading, thread rolling, heat treatment, surface treatment |

| Surface treatment | Black Oxide Coating/Zinc Plating (Electroplating)/Hot-Dip Galvanizing/Mechanical Galvanizing/Dacromet Coating/Painting or Powder Coating |

When specifying set screws, it’s important to consider the requirements of your application to ensure that the chosen set screw is compatible with the materials, forces, and conditions it will encounter.

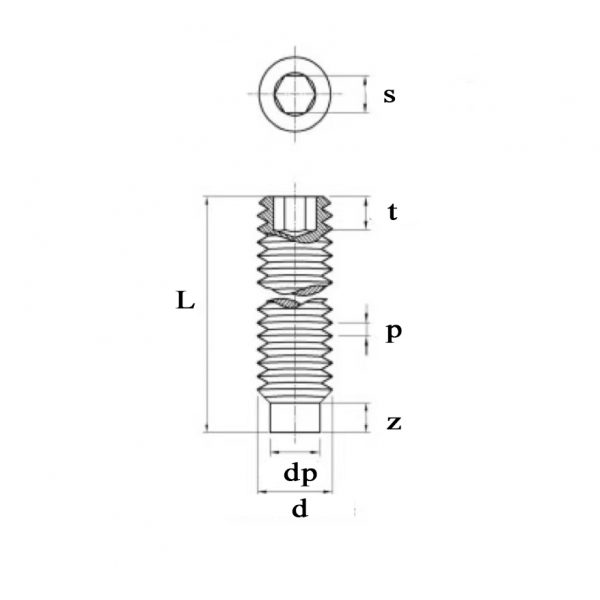

Dimension Chart of DIN915 Hexagon Socket Set Screw:

1. Thread Diameter (d): The thread diameter of a DIN 913 set screw refers to the main diameter of its threads, typically measured in millimeters.

2. Thread Pitch (p): Thread pitch indicates the distance between threads on the screw and is measured in millimeters. It is a crucial dimension for DIN 913 set screws.

3. Hex Key Size (Across Flats) (s): The set screw features an internal hexagon socket for tightening with a hex key or wrench. Hex key size (across flats) is the distance between two parallel hexagonal sides of this socket.

4. Hex Key Depth (t): Hex key depth refers to the depth of the internal hexagon socket, representing the maximum depth a hex key can be inserted into the set screw.

5. Set Screw Length (L): This is the measurement from the bottom of the set screw (or from the end of the threads, in the case of headless set screws) to the end of the threads. It determines how deeply the screw can be threaded into a tapped hole or onto a shaft.

6. Diameter of a dog point (dp): refers to the width or thickness of the cylindrical protrusion on the end of a set screw or similar fastener. In the context of fasteners like set screws, the dog point is a specific type of extended tip designed for easy alignment and initial positioning. The diameter of the dog point is a critical measurement, ensuring proper fit and engagement with the mating surface.

7.The height of the dog point (z): The height of the dog point on a DIN 915 set screw refers to the measurement of the cylindrical protrusion extending from the end of the screw. This dimension is crucial as it determines how far the dog point extends beyond the threaded portion. The height is essential for applications where the set screw is used to locate or align components, providing a reference point.

When L≤L0, it is short screw; When L > L0, it is a long screw.

| Thread Diameter(d) | Thread Pitch(P) | Hex Key Size (s) | Hex Key Depth (t) min Short type screw | Hex Key Depth (t) min Long type screw | Diameter of a dog point (dp) | The height of the dog point (z) Short type screw | The height of the dog point (z) Long type screw | L0 |

| M1.4 | 0.3 | 0.711-0.724 | 0.6 | 1.4 | 0.45-0.7 | 0.4-0.65 | 0.8-1.05 | 2 |

| M1.6 | 0.35 | 0.711-0.724 | 0.7 | 1.5 | 0.55-0.8 | 0.4-0.65 | 0.8-1.05 | 2.5 |

| M1.8 | 0.35 | 0.711-0.724 | 0.8 | 1.6 | 0.65-0.9 | 0.5-0.65 | 1-1.25 | 3 |

| M2 | 0.4 | 0.889-0.902 | 0.8 | 1.7 | 0.75-1 | 0.5-0.75 | 1-1.25 | 3 |

| M2.5 | 0.45 | 1.27-1.295 | 1.2 | 2 | 1.25-1.5 | 0.63-0.88 | 1.25-1.5 | 4 |

| M3 | 0.5 | 1.52-1.545 | 1.2 | 2 | 1.75-2 | 0.75-1 | 1.5-1.75 | 5 |

| M4 | 0.7 | 2.02-2.045 | 1.5 | 2.5 | 2.25-2.5 | 1-1.25 | 2-2.25 | 6 |

| M5 | 0.8 | 2.52-2.56 | 2 | 3 | 3.2-3.5 | 1.25-1.5 | 2.5-2.75 | 6 |

| M6 | 1 | 3.02-3.08 | 2 | 3.5 | 3.7-4 | 1.5-1.75 | 3-3.25 | 8 |

| M8 | 1.25 | 4.02-4.095 | 3 | 5 | 5.2-5.5 | 2-2.25 | 4-4.3 | 10 |

| M10 | 1.5 | 5.02-5.095 | 4 | 6 | 6.64-7 | 2.5-2.75 | 5-5.3 | 12 |

| M12 | 1.75 | 6.02-6.095 | 4.5 | 8 | 8.14-8.5 | 3-3.25 | 6-6.3 | 16 |

| M14 | 2 | 6.02-6.095 | 5.6 | 9 | 9.64-10 | 3.5-3.8 | 7-7.36 | 20 |

| M16 | 2 | 8.025-8.115 | 6.4 | 10 | 11.57-12 | 4-4.3 | 8-8.36 | 20 |

| M18 | 2.5 | 10.025-10.115 | 7.2 | 11 | 12.57-13 | 4.5-4.8 | 9-9.86 | 25 |

| M20 | 2.5 | 10.025-10.115 | 8 | 12 | 14.57-15 | 5-5.3 | 10-10.36 | 25 |

| M22 | 2.5 | 12.032-12.142 | 9 | 13.5 | 16.57-17 | 5.5-5.8 | 11-11.43 | 30 |

| M24 | 3 | 12.032-12.142 | 10 | 15 | 17.57-18 | 6-6.3 | 12-12.43 | 30 |

Application of DIN915 Set Screw:

DIN 915 set screws with dog points find various applications across industries due to their unique design. Here are common applications:

| Application | Details |

|---|---|

| Positioning and Alignment: | The dog point on DIN 915 set screws is ideal for applications where precise positioning and alignment of components are crucial. It serves as a reference point, aiding in accurate assembly. |

| Fixturing and Tooling: | In manufacturing and machining, DIN 915 set screws are often used in fixturing and tooling applications. The extended dog point helps secure components in place reliably. |

| Mechanical Linkages: | These set screws are employed in mechanical linkages where a secure and non-marring connection is needed. The dog point facilitates a tight fit without damaging the mating surfaces. |

| Equipment and Machinery: | DIN 915 set screws are utilized in various equipment and machinery to prevent unintended movement or misalignment. Their robust design contributes to the stability and reliability of the overall system. |

| Automotive Industry: | In automotive applications, DIN 915 set screws may be used for securing components within the engine, transmission, or other critical systems, where precise positioning is essential. |

| Electronics: | The set screws are also applied in electronics manufacturing, providing a reliable and adjustable connection for components or modules within devices. |

Quality Control of Set Screw:

Our quality control measures extend to torque resistance and hardness testing, guaranteeing that every product meets or exceeds industry standards. With a relentless dedication to quality assurance, we take pride in delivering reliable and top-notch set screws to meet the diverse needs of our valued customers.

| Control Method | Detail |

|---|---|

| Material Inspection: | Verify the material's composition, heat treatment, and quality upon receipt. Conduct metallurgical analysis to ensure the material properties meet the standards. |

| Process Control: | Implement strict process control measures for heat treatment, machining, threading, and any other manufacturing steps. Maintain consistent process parameters to ensure uniform quality. |

| Equipment Calibration: | Regularly calibrate manufacturing equipment to ensure accurate measurements and consistent results. |

| Inspection Points: | Introduce inspection points at various stages of manufacturing to check for defects, dimensions, and quality. Inspect threading, dimensions, surface finish, and other critical parameters. |

| Sampling and Testing: | Regularly sample products for testing, such as tensile testing, hardness testing, and metallurgical analysis, to ensure they meet the required specifications. |

| Thread Inspection: | Thoroughly inspect threading using proper thread gauges to ensure accurate dimensions and fit with mating components. |

| Traceability: | Implement a traceability system to track each fasteners journey from raw material to final product. This aids in accountability and recalls if necessary. |