IFI145 Hex Serrated Flange Nuts Supplier Exporter In China

Ningbo Teng Qi Fasteners Co., Ltd is a China supplier of IFI 145 flange nuts. Based on many years of experience and advanced production equipment, we provide customers with products in various specifications ranging from #6 to 3/4 inches. We use high-quality materials and advanced production processes to ensure stable and reliable product quality.

Our IFI 145 flange nuts have the following features: First, we offer a wide range of size options, from #6 to 3/4 inches, to meet customers’ different needs and application scenarios. Secondly, we use high-quality materials to ensure that the products have excellent strength and durability and can cope with the requirements of various engineering environments. At the same time, we have advanced cold heading production equipment and technical teams, which can achieve precision production and strict quality control of products, ensuring accurate product dimensions and smooth surfaces. Most importantly, our IFI 145 flange nuts have good locking performance and anti-loosening features, ensuring a solid and reliable connection. IFI 145 flange nuts are widely used in construction, machinery manufacturing, automobile industry and other fields. Whether connecting threaded components or fixing structures, our products ensure a secure connection between equipment and structures. We strictly abide by the quality management system, and all products undergo strict quality testing and review to ensure stable and reliable product quality. Our goal is to provide customers with high-quality products that meet their needs and earn their trust.

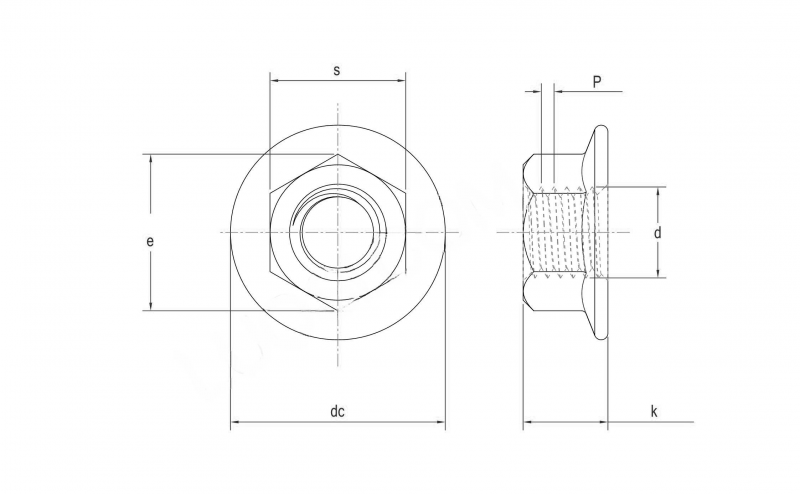

Specification of IFI 145 Hex Serrated Flange Nut:

The specification of IFI 145 Hex Flange Nut include the following details:

| Product name | IFI 145 Hex Flange Nut |

|---|---|

| Thread Diameter: | #6-3/4" |

| Thread Type: | UNC/UNF Class 2B ASME B1.1 |

| Grade | SAE J 995 GR.2 / GR.5 A2-70/A4-80 |

| Material: | GR.2: Q235 Low Carbon Steel GR.5: 1035 Medium Carbon Steel A2-70: SS304 A4-80: SS316 |

| Surface Treatment | Zinc Plated/Plain/Dacromet |

| Packaging: | Boxes/cartons into wooden pallets |

Dimension Chart of IFI145 Hexagon Flange Nut:

| Thread Diameter | #6 | #8 | #10 | #12 | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 9/16 |

| P | 32|40 | 32|36 | 24|32 | 24|28|32 | 20|28|32 | 18|24|32 | 16|24|32 | 14|20|28 | 13|20|28 | 12|18|24 |

| s max | 0.312 | 0.344 | 0.375 | 0.438 | 0.438 | 0.5 | 0.562 | 0.688 | 0.75 | 0.875 |

| s min | 0.302 | 0.334 | 0.365 | 0.428 | 0.428 | 0.489 | 0.551 | 0.675 | 0.736 | 0.861 |

| e max | 0.361 | 0.397 | 0.433 | 0.505 | 0.505 | 0.577 | 0.65 | 0.794 | 0.866 | 1.01 |

| e min | 0.342 | 0.381 | 0.416 | 0.488 | 0.488 | 0.557 | 0.628 | 0.768 | 0.84 | 0.982 |

| dc max | 0.422 | 0.469 | 0.5 | 0.954 | 0.954 | 0.68 | 0.75 | 0.937 | 1.031 | 1.188 |

| dc min | 0.406 | 0.452 | 0.48 | 0.574 | 0.574 | 0.66 | 0.728 | 0.91 | 1 | 1.155 |

| k max | 0.171 | 0.203 | 0.219 | 0.236 | 0.236 | 0.283 | 0.347 | 0.395 | 0.458 | 0.506 |

| k min | 0.156 | 0.187 | 0.203 | 0.222 | 0.222 | 0.268 | 0.33 | 0.375 | 0.437 | 0.483 |

1. Tops of Nuts. Tops of nuts shall be flat and chamfered, the length of chamfer at hex corners shall be from 5 to 15 percent of the basic thread size. The surface may be slightly convex or rounded.

2. Bearing Surface. Bearing surface shall be at right angle to axis of the threaded hole within a tolerance of 2 degrees; therefore, the maximum total angularity of bearing surface would equal the tangent of specified angle times the diameter of the flange.

3. Concentricity of Tapped Hole. Axis of tapped hole shall be concentric with axis of nut body within a tolerance equal to 3 percent (6 percent FIM) of the maximum width across flats.

4. Countersink. Tapped hole shall be countersunk on the bearing face and may be countersunk on the top. The maximum countersunk diameter shall be the thread basic (nominal) major diameter plus 0.030 in. for 3/8 in. nominal size nuts and smaller, and 1.08 times the basic major diameter for nuts larger than 3/8 in. No part the thread portion shall project beyond the bearing-surface.

- RELATED NUT LISTS:

- DIN6334 Hexagon Coupling Nuts

- ASME/ANSI B 18.2.2 Hex Slotted Nuts/Castle Nuts

- ASME/ANSI B18.2.2 Hex Flange Nuts

- Lock Nuts

- DIN982 Nylon Lock Nuts

- DIN985 Nylon Lock Nuts

- ASME B 18.16.6 Nylon Nuts

- HEX NUT

- JIS 1186 Hex Nuts

- DIN934 Hex Nuts

- A194 Hex Nuts

- A563 Hex Nuts

- DIN6915 Hex Nuts

- GOST 28919 Thick Hex Nuts

- GOST R 52645 Structural Hex Nuts

- GOST 5915 Hex Nut

- UNI5588 Hex Nuts

- UNI5587 Thick Hex Nuts

- UNI5713 Hex Nuts

- AS1112.1 Hex Nuts

- AS1252 Hex Nuts

- AS/NZS 2451 Hex Nuts

- AS/NZS 2465 Hex Nuts

- DIN6330 Hex Thick Nuts

- ASME/ANSI B 18.2.2 Hex Thick Nuts

Application of IFI 145 Hex Flange Nuts:

The IFI 145 flange nut, also known as a serrated flange nut, finds application in various industries and scenarios due to its unique design and functionality. Here are some common applications:

| Application | Details |

|---|---|

| Automotive Industry: | IFI 145 flange nuts are extensively used in automotive manufacturing and repair. They are commonly found in vehicle chassis, engines, suspension systems, and exhaust systems. The serrated flange design helps prevent loosening due to vibration, providing a secure fastening solution in high-stress automotive applications. |

| Construction: | In the construction industry, IFI 145 flange nuts are utilized for securing structural components such as beams, columns, and trusses. Their serrated flanges offer enhanced grip and resistance to loosening, making them suitable for applications subjected to heavy loads and dynamic forces. |

| Machinery and Equipment: | Machinery and equipment manufacturers rely on IFI 145 flange nuts to secure moving parts, fasten components, and ensure equipment reliability. These nuts are commonly used in agricultural machinery, industrial machinery, and material handling equipment where vibration and movement are prevalent. |

| Electronics: | In electronic equipment and appliances, IFI 145 flange nuts are used for securing components and assemblies. Their serrated flanges provide a secure grip, making them suitable for applications where reliability and stability are essential, such as in electrical enclosures and control panels. |

| Railroad and Transportation: | IFI 145 flange nuts are employed in railroad and transportation infrastructure for securing tracks, rail components, and signaling equipment. The serrated flange design helps maintain bolt tension and prevents loosening, ensuring the safety and reliability of railway systems. |

| Marine and Offshore: | In marine and offshore applications, where exposure to harsh environments and vibrations is common, IFI 145 flange nuts are used for securing components on ships, offshore platforms, and marine structures. Their serrated flanges provide added resistance to corrosion and loosening in saltwater environments. |

| Power Generation: | IFI 145 flange nuts are utilized in power generation facilities, including fossil fuel, nuclear, and renewable energy plants. They are used for securing turbines, generators, piping systems, and structural components, ensuring safe and reliable operation in demanding environments. |