DIN125 Germany Standard Flat Washer Manufacturer In China

Ningbo Teng Qi Fasteners Co., Ltd is a professional manufacturer of Germany Standard DIN125 flat washers, equipped with advanced punching machines that enable us to produce a diverse range of sizes with utmost precision. Our expertise in the manufacturing process ensures that each flat washer meets the highest standards of quality and reliability, making us a trusted choice for industrial applications.

With a wide selection of materials including stainless steel, carbon steel, aluminum, and copper, we offer versatility to meet the specific needs of our customers. Moreover, our commitment to excellence extends to surface treatments such as black oxidation, zinc plating, dacromet, and hot-dip galvanizing, providing added durability and corrosion resistance. Through strict quality control measures including hardness testing and dimensional precision checks, we guarantee that every flat washer leaving our facility is of superior quality, meeting the stringent requirements of our customers. Trust us for premium DIN125 flat washers that deliver unmatched performance and reliability in diverse industrial settings.

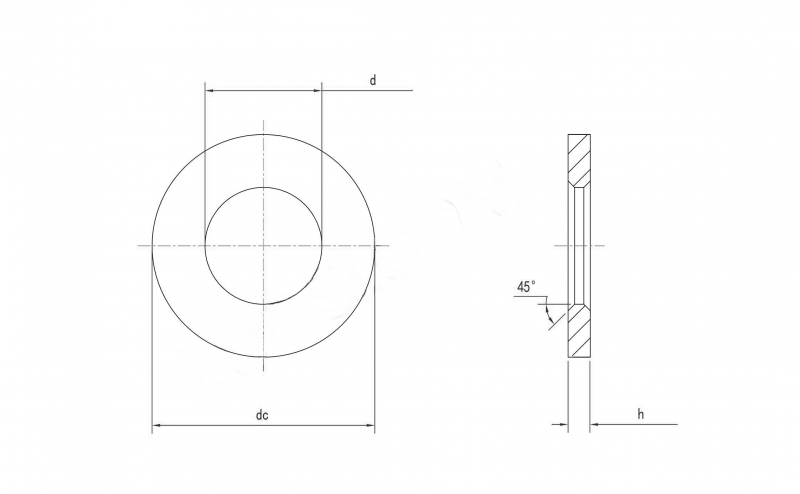

Specification of Germany Standard DIN125 Flat Washer:

The Germany Standard DIN 125 specification outlines the requirements for flat washers, also known as plain washers, used in various mechanical and structural applications. Here are the key specifications for DIN 125 flat washers:

| Material: | Carbon Steel: Q235/C45 Stainless Steel: SS304/SS316/SS2205/SS321/904L |

| Inner Diameter: | Φ1.5-Φ120 |

| Surface Finish: | Black Oxidation/Zinc Plated/Hot Dip Galvanized/Dacromet/Nickel Plated |

| Surface Roughness: | According to DIN522 |

| Application: | Automotive, construction, and industrial applications where reliable and efficient fastening is required. |

| Hardness: | 140HV/200HV/300HV |

Dimension Chart of DIN125 Flat Washer:

| Thread Diameter | Φ1.6 | Φ2 | Φ2.4 | Φ2.5 | Φ2.6 | Φ3 | Φ3.5 | Φ4 | Φ5 | Φ6 | Φ7 | Φ8 | Φ10 | Φ12 | Φ14 | Φ16 | Φ18 | Φ20 | Φ22 | Φ24 | Φ26 | Φ27 | Φ28 | Φ30 | Φ32 | Φ33 | Φ35 | Φ36 |

| d min | 1.7 | 2.2 | 2.5 | 2.7 | 2.8 | 3.2 | 3.7 | 4.3 | 5.3 | 6.4 | 7.4 | 8.4 | 10.5 | 13 | 15 | 17 | 19 | 21 | 23 | 25 | 27 | 28 | 29 | 31 | 33 | 34 | 36 | 37 |

| d max | 1.84 | 2.34 | 2.64 | 2.84 | 2.94 | 3.38 | 3.88 | 4.48 | 5.48 | 6.62 | 7.62 | 8.62 | 10.77 | 13.27 | 15.27 | 17.27 | 19.33 | 21.33 | 23.33 | 25.33 | 27.33 | 28.33 | 29.33 | 31.39 | 33.62 | 34.62 | 36.62 | 37.62 |

| dc max | 4 | 5 | 6 | 6 | 7 | 7 | 8 | 9 | 10 | 12 | 14 | 16 | 20 | 24 | 28 | 30 | 34 | 37 | 39 | 44 | 50 | 50 | 50 | 56 | 60 | 60 | 66 | 66 |

| dc min | 3.7 | 4.7 | 5.7 | 5.7 | 6.64 | 6.64 | 7.64 | 8.64 | 9.64 | 11.57 | 13.57 | 15.57 | 19.48 | 23.48 | 27.48 | 29.48 | 33.38 | 36.38 | 38.38 | 43.38 | 49.38 | 49.38 | 49.38 | 55.26 | 58.8 | 58.8 | 64.8 | 64.8 |

| h max | 0.35 | 0.35 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.9 | 1.1 | 1.8 | 1.8 | 1.8 | 2.2 | 2.7 | 2.7 | 3.3 | 3.3 | 3.3 | 3.3 | 4.3 | 4.3 | 4.3 | 4.3 | 4.3 | 5.6 | 5.6 | 5.6 | 5.6 |

| h min | 0.25 | 0.25 | 0.45 | 0.45 | 0.45 | 0.45 | 0.45 | 0.7 | 0.9 | 1.4 | 1.4 | 1.4 | 1.8 | 2.3 | 2.3 | 2.7 | 2.7 | 2.7 | 2.7 | 3.7 | 3.7 | 3.7 | 3.7 | 3.7 | 4.4 | 4.4 | 4.4 | 4.4 |

Application of DIN125 Flat Washer:

| General Construction: | DIN 125 washers are extensively used in construction projects for securing structural components like beams, columns, and trusses. They provide a smooth bearing surface and distribute the load of fasteners, ensuring stability and durability in building structures. |

| Machinery Assembly | In machinery assembly and manufacturing processes, DIN 125 washers play a crucial role in securing moving parts, housings, and components. They help prevent wear and damage to mating surfaces, ensuring smooth operation and longevity of machinery. |

| Automotive Industry: | DIN 125 flat washers are used in automotive manufacturing and repair applications, such as engine assembly, chassis construction, and vehicle maintenance. They provide support and reinforcement for critical fastening points in automotive systems. |

| Electrical and Electronic Equipment: | DIN 125 washers are employed in the assembly of electrical and electronic equipment, including appliances, control panels, and electronic enclosures. They help distribute pressure and maintain proper alignment in fastening connections. |

| Plumbing and Pipework: | In plumbing and pipework installations, DIN 125 washers are used to secure fittings, connectors, and valves. They provide a reliable seal and prevent leakage in fluid and gas systems. |

| Industrial Machinery: | DIN 125 washers are essential components in industrial machinery and equipment, including conveyor systems, material handling equipment, and industrial pumps. They contribute to the stability and integrity of mechanical assemblies in industrial settings. |