Hydraulic Hose Fittings Supplier Trader In China

Ningbo Teng Qi Fasteners Co., Ltd is a leading hydraulic hose fitting supplier in China, we take pride in being a leading manufacturer of high-quality hydraulic fittings, catering to the diverse needs of industries worldwide. With a commitment to excellence and precision engineering, we offer a wide range of premium hydraulic fittings designed to ensure optimal performance and reliability in hydraulic systems.

Our Product Range:

1. Hose Ferrule: Precision-engineered hose ferrules for secure hose connections.

2. Swaged Hose Fittings: Expertly crafted fittings for robust and leak-free hydraulic connections.

3. One Piece Hose Fitting: Seamless one-piece fittings designed for ease of installation.

4. Interlock Hose Fittings: Interlocking fittings ensuring enhanced stability and durability.

5. Reusable Hose Fittings: Environmentally friendly fittings allowing multiple uses without compromising quality.

6. Socketless Hose Fittings: Innovative fittings for easy and efficient hose assembly.

7. Fuel Hose Swivel Joint: Specialized fittings designed for reliable fuel transfer applications.

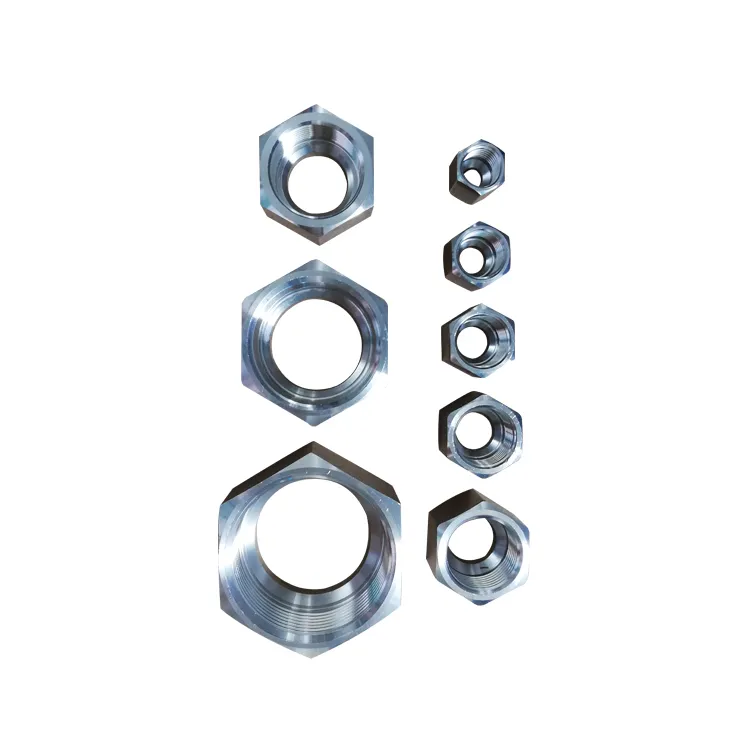

Specification of Hydraulic Hose Fittings:

Hydraulic hose fittings come in various specifications to meet different requirements in hydraulic systems. Here are some common specifications you might find for hydraulic hose fittings

Thread Size:

Come with specific thread sizes, which are usually measured in inches or millimeters. Common thread sizes include 1/4″, 3/8″, 1/2″, and so on.

Hose Inside Diameter:

Fittings are designed to match specific hose inside diameters. Common sizes include 1/4″, 3/8″, 1/2″, 3/4″, and 1″.

Material:

We utilize premium materials such as carbon steel, SS304, and SS316,brass ensuring durability and longevity in every fitting we produce.

End Configuration:

Fittings can have different end configurations, such as straight, elbow (90 degrees), or tee (T-shaped), allowing for various assembly options in hydraulic systems.

Standards Compliance:

Hydraulic fittings should comply with industry standards like ISO (International Organization for Standardization) or SAE to ensure their compatibility and performance in hydraulic systems.

Surface Treatment Choice:

Fittings often undergo surface treatments like zinc plating, chrome plating, or other coatings to enhance corrosion resistance and improve the overall durability of the fitting.

FAQ about Hydraulic Hose Fittings:

1.What is a hydraulic hose fitting?

A hydraulic hose fitting is a component used to connect hydraulic hoses securely to various hydraulic components, ensuring a leak-free connection and enabling the hydraulic system to function effectively.

2.What is the importance of proper thread size in hydraulic hose fitting?

Choosing the correct thread size is crucial, as it ensures a proper fit and seal between components. Mismatched thread sizes can lead to leaks and compromise the integrity of the hydraulic system.

3.How are hydraulic hose fittings installed?

Hydraulic hose fittings are typically installed using specialized equipment to crimp or swage the fitting onto the hose securely. Proper installation is vital to prevent leaks and ensure the hydraulic system’s efficiency and safety.

4.How are hydraulic hose fittings tested for quality and performance?

How are hydraulic hose fittings tested for quality and performance?

5. How are hydraulic hose fittings manufactured?

The manufacturing process involves forging, machining, surface treatment. Precision is crucial to ensure proper fit and functionality in hydraulic systems.

6.What sets your hydraulic hose fittings apart from others in the market?

We take pride in offering hydraulic hose fittings that combine competitive pricing with superior quality control. Our fittings undergo rigorous testing to ensure durability and performance, making them a reliable choice for various applications.