Nuts Supplier In China

Ningbo Teng Qi Fasteners Co., Ltd is a leading nuts supplier in China. Nuts refer to hardware components used in conjunction with bolts or screws. Nuts are typically threaded internally and are used to secure two or more parts together by providing a mating thread for the bolt or screw. They come in various shapes, sizes, and materials, such as hex nuts, lock nuts, wing nuts, and more. These nuts play a crucial role in fastening applications across industries like construction, automotive, and manufacturing.

Specifications of nuts:

Nuts come in various specifications that define their size, threading, and material. Here are some common specifications you might encounter when dealing with nuts:

| Product name: | Nuts |

| Thread Size: | Metric: M6-M100 Imperial:1/4" to 4" |

| Material: | Steel/Stainless steel/Brass/Aluminum |

| Class: | 5/8/10/12 A2-70 A2-80 A4-70 A4-80 |

| SAE J 995 Grade: | 2/5/8 |

| Manufacturing Process | wire drawing, cold heading/hot forging, thread rolling, heat treatment, surface treatment |

| Surface treatment: | Black Oxide Coating/Zinc Plating (Electroplating)/Hot-Dip Galvanizing/Mechanical Galvanizing/Dacromet Coating/Painting or Powder Coating |

| Application Industry | Construction/Agricultural Machinery/Industrial Structures/Equipment and Machinery/Infrastructure |

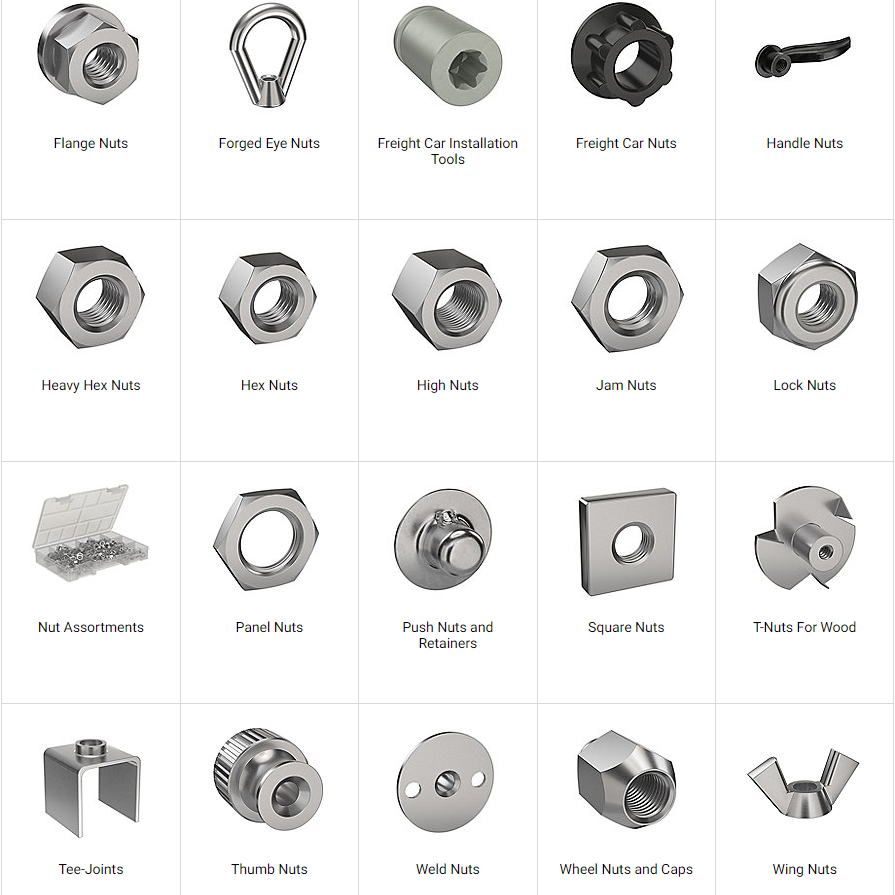

Type of Nuts:

Hex nuts are the most widely used type of nut in industrial and mechanical applications. Featuring a six-sided design, they provide strong and reliable fastening when paired with bolts or screws. Ideal for general-purpose assembly.

Heavy hex nuts have a larger width and thickness compared to standard hex nuts, offering increased strength and load-bearing capability. Commonly used in steel structures, heavy machinery, and high-stress environments.

A nylon lock nut includes a nylon insert at the top that increases friction and prevents loosening under vibration. This type of lock nut is widely used in automotive, machinery, and equipment that requires secure, vibration-resistant fastening.

Flange nuts feature a built-in washer-like flange at the base. This design increases the bearing surface, reduces damage to connected parts, and improves resistance to loosening. Suitable for applications requiring even load distribution.

Dome cap nuts, also known as acorn nuts, have a closed rounded top that protects exposed bolt threads and improves the overall appearance. Commonly used in furniture, bicycles, and safety-related installations.

A coupling nut is a long, hexagonal nut designed to connect two threaded rods or bolts. It is used for extending length, structural adjustments, and various construction or repair applications.

Related products of nuts:

- ISO4032 Hex Nut

- ANSI B18.2.2 Hex Nut

- AS1252 Hex Nut

- DIN6915 Hex Nut

- A194 Heavy Hex Nut

- A563 Heavy Hex Nut

- JIS1186 Hex Nut

- UNI5587 Hex Nut

- DIN6923 Flange Nut

- DIN985 Nylon Nut

- DIN982 Nylon Nut

- DIN1587 Dome Cap Nut

- DIN6334 Coupling Nut

- ASME B 18.16.6 Nylon Nuts

- GOST 5915 Hex Nut

- AS1112.1 Hex Nuts

- DIN6330 Hex Thick Nuts

- RELATED SCREW LISTS:

- Countersunk Head Torx Screw

- Button Round Head Torx Screw

- Cylindrical Head Torx Screw

- Countersunk Head Torx Screw with Pin

- Cylindrical Head Torx Screw with Pin

- Hexagon Socket Countersunk Head Cap Screw

- Hexagon Socket Head Cap Screw

- Flat Countersunk Head Screw with Cross Recess

- Pan Head Screw with Cross Recess

- Slotted Countersunk Head Screw

- Slotted Pan Head Screw

FAQ about nuts:

1.What is the size range of nuts you produce?

Our cold heading equipment support to produce nut from M0.6-M24, hot forging machine support to produce nuts from M24-M100.

2.How many days does it take you to deliver a container of nuts?

Lead times for nut manufacturing can vary depending on factors like the quantity, complexity, and customization requirements. Generally, standard nut are in stock, while custom orders may take several weeks to complete.

3.Can you guarantee the quality of the nuts?

Yes. we strictly control quality from raw materials to final packing, we can ensure that the every nut manufactured by us meet the performance requirements and the materials are traceable.

4.Can you supply stainless steel nuts?

Yes, we are leading fasteners supplier in China. Stainless steel, carbon steel nut all can be supplied, and there is a large stock.

5. Do you have a minimum order quantity requirement?

Yes, the MOQ we usually produce is about one ton. But we have most sizes in stock, so for inventory items, even 10 units we can supply.

6.Can you offer customized packing?

Yes, box/carton/metal bucket are all available, color/label/size all can meet customer requirements.

Quality control of nut:

In a world where connections matter, Ningbo Teng Qi Fasteners is more than just a fasteners supplier and manufacturer. We are architects of stability, builders of relationships, and champions of your success. From skyscrapers that reach for the sky to machines that power industries, our fasteners form the backbone of progress. When you choose Ningbo Teng Qi Fasteners, you choose unwavering quality, exceptional service, and a partner who understands that every bolt holds a piece of your vision.

| Control Method | Detail |

|---|---|

| Material Inspection: | Verify the material's composition, heat treatment, and quality upon receipt. Conduct metallurgical analysis to ensure the material properties meet the standards. |

| Process Control: | Implement strict process control measures for heat treatment, machining, threading, and any other manufacturing steps. Maintain consistent process parameters to ensure uniform quality. |

| Inspection Points: | Introduce inspection points at various stages of manufacturing to check for defects, dimensions, and quality. Inspect threading, dimensions, surface finish, and other critical parameters. |

| Sampling and Testing: | Regularly sample products for testing, such as tensile testing, hardness testing, and metallurgical analysis, to ensure they meet the required specifications. |

| Thread Inspection: | Thoroughly inspect threading using proper thread gauges to ensure accurate dimensions and fit with mating components. |

| Traceability: | Implement a traceability system to track each fasteners journey from raw material to final product. This aids in accountability and recalls if necessary. |