Australia Standard AS1112.1 Hex Nut Manufacturer In China

Ningbo Teng Qi Fasteners Co., Ltd have more than 20 years’ experience in producing AS111.2.1 hex nuts. AS1112 hex nuts are standardized fasteners specified by the Australian Standard AS1112. This standard is equivalent to ISO 4032 and covers the dimensions, materials, and properties of hexagon regular nuts with metric coarse pitch threads. These nuts are typically used in mechanical and engineering applications for fastening purposes. They come in various materials such as steel, stainless steel, and are available in different finishes to suit specific requirements.

Specification of AS1112 Hex Nut:

The specification of as1112 hex nuts include the following details:

| Product name | AS1112 Hex Nuts |

|---|---|

| Thread Diameter: | M1.6-M64 |

| Thread Tolerance: | 6H |

| Material: | Class5:Q235 Class 8 : C45 Class10 : C45 Class12 : 42Crmo A2-70/A2-80:SS304 A4-70/A4-80:SS316 |

| Finish and Coating: | Black Oxide Coating/Zinc Plating (Electroplating)/Hot-Dip Galvanizing/Mechanical Galvanizing/Dacromet Coating/Painting or Powder Coating |

| Packaging: | Boxes/cartons into wooden pallets |

| Application: | Construction/Agricultural Machinery/Industrial Structures/Equipment and Machinery/Infrastructure |

- RELATED NUT LISTS:

- DIN6334 Hexagon Coupling Nuts

- ASME/ANSI B 18.2.2 Hex Slotted Nuts/Castle Nuts

- ASME/ANSI B18.2.2 Hex Flange Nuts

- Lock Nuts

- IFI145 Flange Nuts

- DIN982 Nylon Lock Nuts

- DIN985 Nylon Lock Nuts

- ASME B 18.16.6 Nylon Nuts

- HEX NUT

- JIS 1186 Hex Nuts

- DIN934 Hex Nuts

- A194 Hex Nuts

- A563 Hex Nuts

- DIN6915 Hex Nuts

- GOST 28919 Thick Hex Nuts

- GOST R 52645 Structural Hex Nuts

- GOST 5915 Hex Nut

- UNI5588 Hex Nuts

- UNI5587 Thick Hex Nuts

- UNI5713 Hex Nuts

- AS1252 Hex Nuts

- AS/NZS 2451 Hex Nuts

- AS/NZS 2465 Hex Nuts

- DIN6330 Hex Thick Nuts

- ASME/ANSI B 18.2.2 Hex Thick Nuts

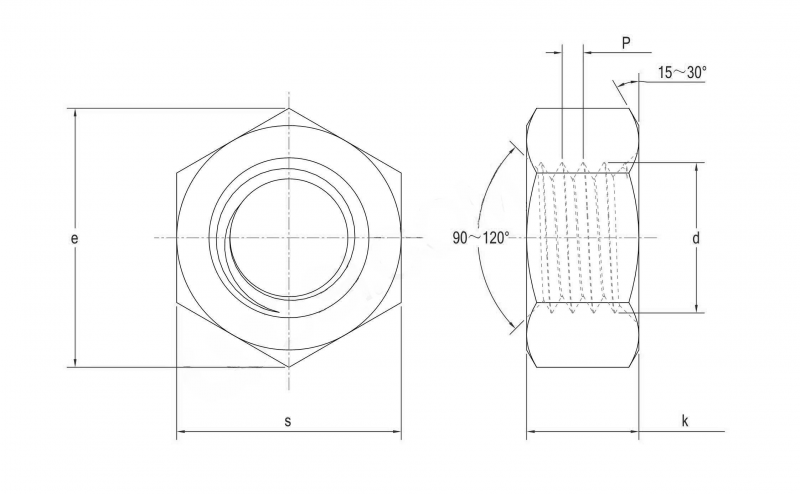

Dimension Chart of AS1112 Hex Nut:

| Thread Diameter(d) | Thread Pitch(P) | Width Across Flat (s) | Width Across Corner(e) Min | Height (k) |

| M1.6 | 0.35 | 3.02-3.2 | 3.41 | 1.05-1.3 |

| M2 | 0.4 | 3.82-4 | 4.32 | 1.35-1.6 |

| M3 | 0.5 | 5.32-5.5 | 6.01 | 2.15-2.4 |

| M4 | 0.7 | 6.64-7 | 7.5 | 2.9-3.2 |

| M5 | 0.8 | 7.64-7.78 | 8.63 | 4.4-4.7 |

| M6 | 1 | 9.64-10 | 10.89 | 4.9-5.2 |

| M8 | 1.25 | 12.57-12.73 | 14.2 | 6.44-6.8 |

| M10 | 1.5 | 16.57-16.73 | 18.72 | 8.04-8.4 |

| M12 | 1.75 | 18.48-19 | 20.88 | 10.37-10.8 |

| M14 | 2 | 21.16-21.67 | 23.91 | 12.1-12.8 |

| M16 | 2 | 23.16-23.67 | 26.17 | 14.1-14.8 |

| M18 | 2.5 | 26.15-26.67 | 29.56 | 15.1-15.8 |

| M20 | 2.5 | 29.16-29.67 | 32.95 | 16.9-18 |

| M22 | 2.5 | 31-32 | 35.03 | 18.1-19 |

| M24 | 3 | 35-36 | 39.55 | 20.2-21.5 |

| M27 | 3 | 40-41 | 45.2 | 22.5-23.8 |

| M30 | 3.5 | 45-46 | 50.85 | 24.3-25.6 |

| M33 | 3.5 | 49-50 | 55.37 | 27.4-28.7 |

| M36 | 4 | 53.8-55 | 60.79 | 29.4-31 |

| M39 | 4 | 58.8-60 | 66.44 | 31.8-33.4 |

| M42 | 4.5 | 63.1-65 | 71.3 | 32.4-34 |

| M45 | 4.5 | 68.1-70 | 76.95 | 34.4-36 |

| M48 | 5 | 73.1-75 | 82.6 | 36.4-38 |

Application of AS1112 Hex Nut:

| Application | Details |

|---|---|

| Industrial Equipment | AS1112 hex nuts could be employed in various industrial equipment applications where high-strength fastening is required, such as in heavy machinery, manufacturing equipment, or oil and gas extraction machinery. |

| Structural Engineering | In structural engineering projects where high-strength fasteners are necessary, AS1112 hex nuts might be used in applications such as bridge construction, high-rise buildings, or infrastructure projects. |

| Marine Engineering | AS1112 hex nuts could find application in marine engineering projects for securing components in ships, submarines, offshore platforms, or underwater exploration equipment. |

| Rail Transportation | AS1112 hex nuts could be utilized in the construction and maintenance of rail systems, including fastening rails to sleepers, securing overhead lines, and assembling train carriages and locomotives. |

| Renewable Energy Infrastructure | AS1112 hex nuts apply in renewable energy projects, such as securing components in wind turbines, solar panel mounting systems, hydroelectric generators, and geothermal power plants. |

| Telecommunications Infrastructure | In the telecommunications industry, AS1112 hex nuts could be used for securing antennas, communication towers, satellite dishes, and other infrastructure components. |

| Medical Equipment | AS1112 hex nuts might be utilized in the manufacturing of medical equipment and devices, including MRI machines, surgical instruments, patient beds, and diagnostic machinery. |

| Oil and Gas Exploration | AS1112 hex nuts might find application in the oil and gas industry for assembling drilling equipment, pipelines, offshore platforms, and subsea infrastructure. |

Quality Control:

We produce in strict accordance with the requirements specified in the standard documents. The size standard accurately meets the requirements of AS1112 drawings, and the mechanical properties meet the requirements of ISO898-2. Surface treatment electroplating requirements in accordance with ISO4042. The surface defects conform to ISO6157-2.

| Control Method | Detail |

|---|---|

| Material Inspection: | Verify the material's composition, heat treatment, and quality upon receipt. Conduct metallurgical analysis to ensure the material properties meet the standards. |

| Process Control: | Implement strict process control measures for heat treatment, machining, threading, and any other manufacturing steps. Maintain consistent process parameters to ensure uniform quality. |

| Inspection Points: | Introduce inspection points at various stages of manufacturing to check for defects, dimensions, and quality. Inspect threading, dimensions, surface finish, and other critical parameters. |

| Sampling and Testing: | Regularly sample products for testing, such as tensile testing, hardness testing, and metallurgical analysis, to ensure they meet the required specifications. |

| Thread Inspection: | Thoroughly inspect threading using proper thread gauges to ensure accurate dimensions and fit with mating components. |

| Traceability: | Implement a traceability system to track each fasteners journey from raw material to final product. This aids in accountability and recalls if necessary. |