DIN934 Hex Nut Supplie in China

Ningbo Teng Qi Fasteners Co., Ltd is a supplier of DIN 934 standard hex nuts in China, committed to providing high-quality products. Our range includes various materials such as carbon steel and stainless steel to meet diverse application requirements. Following the DIN 934 standard, our hex nuts adhere to specified dimensions, ensuring perfect compatibility with corresponding bolts for a wide range of bolt and thread connection applications.

DIN 934 hex nuts refer to hexagonal nuts that adhere to the specifications outlined by the German Industrial Standard (DIN) 934. These hex nuts are designed for use with bolts and screws in various applications. The DIN 934 standard provides specific requirements for metric hex nuts, including dimensions, tolerances, and material specifications. These hex nuts have a six-sided shape and are commonly used in conjunction with bolts to create a secure fastening system. The standardization ensures that hex nuts manufactured according to DIN 934 specifications are interchangeable and compatible with bolts that follow the same standard.

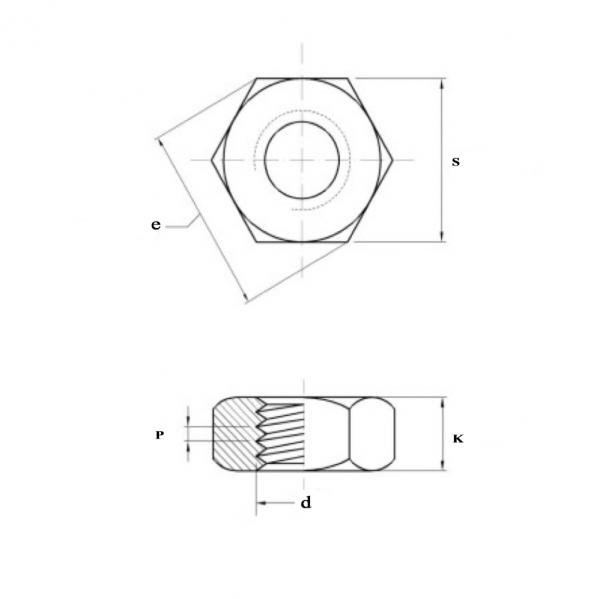

Specification of DIN934 Hex Nuts

The DIN 934 standard specifies the dimensions and requirements for metric hex nuts. Here are some key specifications for DIN 934 hex nuts:

| Product name | DIN934 Hex Nuts |

|---|---|

| Thread Size | This is the nominal diameter of the threaded section, measured in millimeters. For example, a common notation for a hex nut's thread specification could be M12 x 1.75, where: - "M" stands for metric, - "12" is the nominal diameter of the thread in millimeters, and - "1.75" is the pitch of the thread in millimeters. |

| Material | Common materials for DIN 934 hex nuts include carbon steel, stainless steel, and other alloys, depending on the specific requirements of the application. |

| Class | Hex nuts can be classified into different strength grades, such as 5, 6, 8, 10, and 12. Additionally, stainless steel like A2-70, A2-80, A4-70, and A4-80 may be specified for certain applications. |

| Hardness | Class5: 130-302HV (M8×1 ≤ D ≤ M16×1,5) 146-302HV (M16 < D ≤ M39) Class8: 200-302HV (M8×1 ≤ D ≤ M16×1,5) 233-302HV (M16 < D ≤ M39) Class10: 272-353HV (M8×1 ≤ D ≤ M39) Class12: 295-302HV (M8×1 ≤ D ≤ M16×1,5) 272-302HV (M16 < D ≤ M39) |

| Surface treatment | DIN 934 hex nuts undergo various surface treatments, including but not limited to galvanization, blackening, hot-dip galvanizing, and dacromet. These treatments enhance corrosion resistance and appearance. |

Dimension Chart of DIN934 Hex Nuts:

| Thread Diameter(d) | Thread Pitch(P) | Width Across Flat (s) | Width Across Corner(e) Min | Height (k) |

| M1.6 | 0.35 | 3.02-3.2 | 3.41 | 1.05-1.3 |

| M2 | 0.4 | 3.82-4 | 4.32 | 1.35-1.6 |

| M3 | 0.5 | 5.32-5.5 | 6.01 | 2.15-2.4 |

| M4 | 0.7 | 6.64-7 | 7.5 | 2.9-3.2 |

| M5 | 0.8 | 7.64-7.78 | 8.63 | 3.7-4 |

| M6 | 1 | 9.64-10 | 10.89 | 4.7-5 |

| M8 | 1.25 | 12.57-12.73 | 14.2 | 6.14-6.5 |

| M10 | 1.5 | 16.57-16.73 | 18.72 | 7.64-8 |

| M12 | 1.75 | 18.48-19 | 20.88 | 9.64-10 |

| M14 | 2 | 21.16-21.67 | 23.91 | 10.3-11 |

| M16 | 2 | 23.16-23.67 | 26.17 | 12.3-13 |

| M18 | 2.5 | 26.15-26.67 | 29.56 | 14.3-15 |

| M20 | 2.5 | 29.16-29.67 | 32.95 | 14.9-16 |

| M22 | 2.5 | 31-32 | 35.03 | 16.9-18 |

| M24 | 3 | 35-36 | 39.55 | 17.7-19 |

| M27 | 3 | 40-41 | 45.2 | 20.7-22 |

| M30 | 3.5 | 45-46 | 50.85 | 22.7-24 |

| M33 | 3.5 | 49-50 | 55.37 | 24.7-26 |

| M36 | 4 | 53.8-55 | 60.79 | 27.4-29 |

| M39 | 4 | 58.8-60 | 66.44 | 29.4-31 |

| M42 | 4.5 | 63.1-65 | 71.3 | 32.4-34 |

| M45 | 4.5 | 68.1-70 | 76.95 | 34.4-36 |

| M48 | 5 | 73.1-75 | 82.6 | 36.4-38 |

| M52 | 5 | 78.1-80 | 88.25 | 40.4-42 |

Quality Control :

Quality control for DIN 934 hex nuts involves a thorough assessment of various aspects to ensure they meet the standard specifications. Here are key elements of quality control:

| Control Method | Detail |

|---|---|

| Dimensional Accuracy: | Verify that the hex nuts conform to the specified dimensions outlined in DIN 934. This includes checking the thread pitch, diameter, and overall geometry to ensure they align with the standard. |

| Material Inspection: | Ensure that the materials used, whether carbon steel, stainless steel, or other alloys, comply with DIN 934 requirements for strength, corrosion resistance, and other relevant properties. |

| Thread Inspection: | Examine the thread quality to confirm it meets DIN 934 standards. This involves assessing thread pitch, angle, and overall conformance to the specified thread profile. |

| Hardness Testing: | Conduct hardness tests, especially for graded hex nuts, to ensure they meet the specified mechanical strength requirements outlined in DIN 934. |

| Proof Load Test: | Conduct a proof load test on a sample of hex nuts to verify their load-bearing capacity. This involves subjecting the nuts to a predetermined load, typically a percentage of the ultimate tensile strength. The nuts should withstand this load for a specified duration without exhibiting signs of failure, ensuring they meet the load-bearing requirements outlined in DIN 934. |

FAQ:

1. Could you tell me about your DIN934 hex nut production capacity?

Our manufacturing facility is equipped with three sets of hot forging machines and four sets of cold heading machines. This enables us to produce approximately 600 tons of DIN934 hex nut each month.

2. What’s the typical delivery time for a shipment of DIN934 hex nut?

While our daily production capacity for DIN934 hex nuts is around 20 tons, the production process involves material preparation, heat treatment, surface treatment, and order scheduling. As a result, the average delivery time for a container of DIN934 hex nut ranges from 30 to 40 days.

3. Can you share your quality control practices for DIN934 hex nut production?

Our quality control measures encompass meticulous dimensional checks, rigorous thread quality inspections, comprehensive material composition testing, and a thorough evaluation of surface finishes. These practices ensure that our DIN934 nuts consistently meet the specified standards.

4. Do you offer samples of DIN934 hex nuts?

Certainly, we maintain a stock of standard-sized DIN934 nuts for sampling purposes. These samples are provided free of charge; however, the customer is responsible for covering the shipping costs.

5. Are you capable of producing M64 DIN934 hex nuts?

Yes, our hot forging equipment is capable of producing DIN934 nuts up to M100, including M64 hex nuts.

6. Which countries do you export your DIN934 hex nut to?

Over the past decade, we have built strong and enduring relationships with customers in various countries, including the United States, Germany, Russia, Poland, Spain, Brazil, Argentina, Vietnam, Canada, Australia, the UAE, Saudi Arabia, and more.