How to choose foundation anchor bolts?

Choosing suitable foundation anchor bolts involves considering various factors to ensure they are appropriate for your specific needs. Here are some steps to help you select the right foundation bolts:

1. Determine the application: Identify the purpose and usage of the foundation bolts. Will they be used for securing equipment, machinery, or structures to the foundation?

2. Material selection: Foundation bolts are typically made from materials like carbon steel, stainless steel, or other alloys. Consider factors such as corrosion resistance and load-bearing capacity when choosing the material.

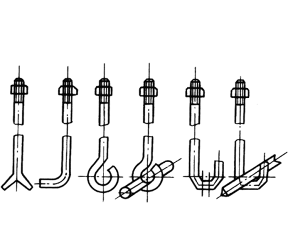

3. Bolt type: There are different types of foundation bolts, such as, J-bolts, U-bolts, and T type anchors. Select the type that best suits your application and load requirements.

4. Size and length: Measure the thickness of the base material and determine the required length of the foundation bolts. Ensure that the bolts are long enough to provide sufficient anchoring depth.

5. Load capacity: Calculate the load that the foundation bolts will bear, including both static and dynamic loads. Choose foundation bolts with the appropriate load capacity to ensure safety and stability.

6. Environmental factors: Consider the environmental conditions the foundation bolts will be exposed to, such as moisture, temperature, and potential corrosive elements. This will help you select bolts with suitable coatings or materials to withstand the conditions.

7. Compliance with regulations: Check if there are any specific building codes or regulations that govern the use of foundation bolts in your area. Ensure the chosen bolts comply with these standards.

By carefully considering these factors and seeking professional advice when needed, you can choose foundation bolts that are suitable for your specific application and provide reliable anchoring support.

| Type and selection of anchor bolts | ||||||

|---|---|---|---|---|---|---|

| The role of the anchor bolt is to firmly connect the equipment to the foundation, so as to avoid displacement and overturn during work. The device is levelled with a pad iron during installation, and then secured with foot bolts | ||||||

| Types | Application | |||||

| Short anchor bolt |  | 1. Often concreted with the foundation 2. It is mainly used to fix medium and small mechanical equipment without strong vibration and shock when working 3. The length is generally 100~1000mm 4. The head of the commonly used death bolt is made into a fork type or a hook shape, as shown in the figure. Hook through a cross bar to prevent the bolt from rotating or pulling out |

||||

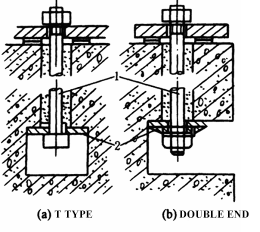

| Long anchor bolt (movable anchor bolt) |  | 1. It is a removable anchor bolt 2. It is mainly used to fix heavy equipment with strong vibration and shock when working 3. The length is generally 1~4m 4. Its shape is divided into two ends with threads and nuts, and hammer (T form), as shown in the figure 5. It is used with the anchor plate. The anchor plate can be welded or cast by steel plate. It has a rectangular or round hole in the middle for threading the bolt |

||||

| Selection | 1. Anchor bolts, nuts and washers are generally brought randomly and should comply with the design and equipment installation instructions. If there is no provision, the following principles can be used: 2. Anchor bolt diameter d < anchor bolt aperture D on the base: |

|||||

| d | M8 | M10 | M12 | M16 | M20 | |

| D | 15 | 17 | 20 | 24 | 28 | |

| d | M24 | M30 | M36 | M42 | M48 | |

| D | 34 | 40 | 46 | 52 | 58 | |

| d | M56 | M64 | M72 | M80 | M90 | |

| D | 66 | 74 | 82 | 90 | 100 | |

| d | M100 | M110 | M125 | M140 | M160 | |

| D | 110 | 120 | 135 | 155 | 175 | |

| 3. The length of anchor bolt according to the construction drawing, if there is no provision, it can be determined by pressing the formula: L1 = 15D+S+(5 to 10)mm Type L1 -- length of anchor bolt, mm D -- Anchor bolt diameter, mm S -- the sum of the height of the cushion iron, the thickness of the frame and the nut, and the reserve (2~3 teeth), mm |

||||||