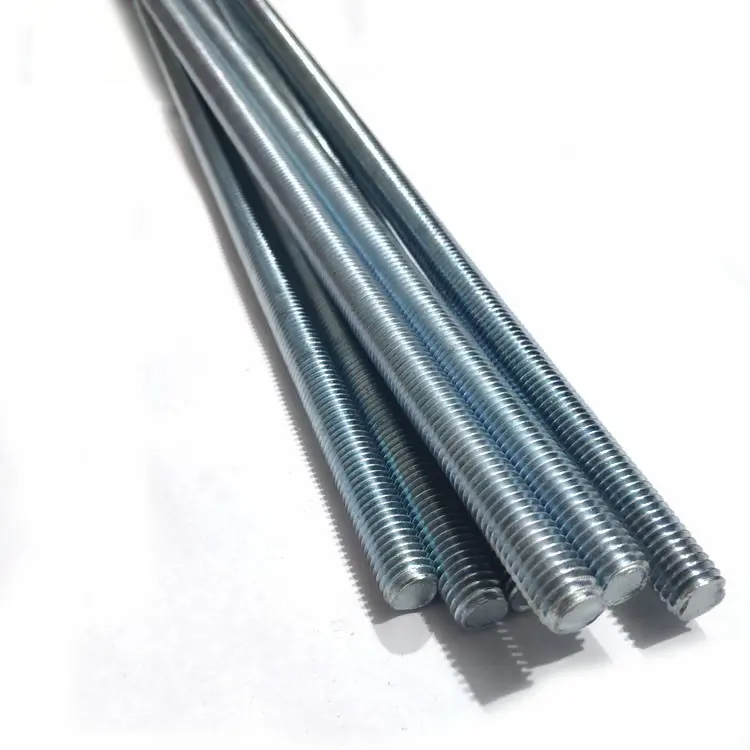

HIGH QUALITY THREADED ROD SUPPLIER IN CHINA

Ningbo Teng Qi Fasteners Co., Ltd is a leading threaded rod manufacturer in China. Threaded rods, also known as threaded studs or all-thread rods, are versatile fasteners used to create secure connections in a wide range of applications. Unlike bolts, threaded rods do not have a head or a specific endpoint. Instead, they are threaded along their entire length, allowing nuts to be fastened at both ends. Threaded rods are available in various materials, diameters, and lengths to suit different needs. The threading allows for bolts and other types of fixings to be fastened onto the rod to suit many different construction applications. Threaded rod is commonly used to connect two objects together, such as wood or metal, or to provide a connection between concrete and another material.

Specification of threaded rod:

Threaded rods, also known as studs, are long, straight metal rods with threads running along their entire length. They are commonly used for fastening and joining applications. The specifications of threaded rods can vary based on the specific requirements of a project, but here are some common specifications:

| Product Name: | Threaded rods |

| Material: | Steel/Stainless steel/Titanium/Nylon/Brass/Copper/Aluminium |

| Thread Type: | Metric/Imperial |

| Diameter: | Metric: M2-M120 Imperial:4#-5“ |

| Class/Grade | ISO898-1 Class 4.8/8.8/10.9/12.9 SAE J429 Grades 2, 5, and 8 A193 B7 A307 Gr.A A449 A320 L7 F1554 Grades 36, 55, and 105 |

| Finish: | Black Oxide Coating/Zinc Plating (Electroplating)/Hot-Dip Galvanizing/Mechanical Galvanizing/Dacromet Coating/Painting or Powder Coating |

| Application: | Construction/Mechanical Engineering/Plumbing/Automotive/Electrical and Electronics |

Threaded rods, also known as studs, are long, straight metal rods with threads running along their entire length. They are commonly used for fastening and joining applications. The specifications of threaded rods can vary based on the specific requirements of a project, but here are some common specifications:

Application of threaded rod:

Threaded rods have a wide range of applications across different industries and sectors due to their versatility and ability to create secure connections over an extended length. Some common applications of Threaded rods include:

| Application | Details |

|---|---|

| Construction: | Threaded rods are used in construction projects for various purposes, such as supporting structures, anchoring heavy equipment, and hanging electrical fixtures or pipes. |

| Plumbing: | They are employed in plumbing applications to secure pipes, fittings, and fixtures in place. |

| Mechanical Engineering: | Threaded rods are used in mechanical engineering projects for assembling and securing machine components, including brackets, supports, and linkages. |

| Building Maintenance: | Threaded rods are used for fixing and suspending items in building maintenance, such as signs, lights, and ceiling grids. |

| Automotive: | In the automotive industry, threaded rods are used for various purposes, such as engine mountings and suspension systems. |

| Electrical and Electronics: | Threaded rods are utilized in electrical and electronic installations to secure panels, enclosures, and equipment. |

| Industrial Machinery: | In manufacturing and industrial settings, threaded rods are used for assembling and aligning machine components and structures. |

| Fastening and Joining: | Threaded rods are used in various applications where a long, continuous fastener is required to join multiple components together. |

| Seismic Bracing: | In seismic bracing systems, threaded rods are used to stabilize and reinforce structures during earthquakes or other seismic events. |

Production procession of threaded rods:

| Wire Drawing: | - The process begins with wire drawing, where steel wire rods or coils are drawn through progressively smaller dies to reduce their diameter while increasing their length. This results in a long, continuous steel wire with the desired diameter. |

| Cutting and Straightening: | The continuous steel wire is then cut into shorter lengths called blanks or slugs. The blanks are straightened to ensure they have uniform dimensions and are free from bends or kinks. |

| Thread Rolling: | The unheaded portion of the blank is threaded using a thread rolling machine. Thread rolling is a cold-forming process where hardened steel dies press onto the blank, creating threads by displacing the material rather than removing it. This process strengthens the threads and improves their fatigue resistance. |

| Heat Treatment: | Threaded rods undergo heat treatment processes, such as quenching and tempering, to achieve the desired mechanical properties. Heat treatment enhances the strength, hardness, and durability of the threaded rods, making them suitable for load-bearing applications. |

| Coating and Plating: | Depending on the intended use and environment, threaded rods may undergo coating or plating processes to enhance corrosion resistance and aesthetics. Common coatings include zinc plating, hot-dip galvanizing, and other protective finishes. |

| Packaging: | Once the threaded rods pass quality checks, they are packaged in bundles or containers suitable for transportation and storage. |

Throughout these manufacturing processes, attention to detail, adherence to industry standards, and quality control measures ensure that the threaded rods meet the required specifications for strength, performance, and reliability.

Threaded rod quality control:

Check our strict quality control in the production procession of threaded rods:

| Control Method | Detail |

|---|---|

| Material Inspection: | Verify the material's composition, heat treatment, and quality upon receipt. Conduct metallurgical analysis to ensure the material properties meet the standards. |

| Process Control: | Implement strict process control measures for heat treatment, machining, threading, and any other manufacturing steps. Maintain consistent process parameters to ensure uniform quality. |

| Inspection Points: | Introduce inspection points at various stages of manufacturing to check for defects, dimensions, and quality. Inspect threading, dimensions, surface finish, and other critical parameters. |

| Sampling and Testing: | Regularly sample products for testing, such as tensile testing, hardness testing, and metallurgical analysis, to ensure they meet the required specifications. |

| Thread Inspection: | Thoroughly inspect threading using proper thread gauges to ensure accurate dimensions and fit with mating components. |

| Traceability: | Implement a traceability system to track each fasteners journey from raw material to final product. This aids in accountability and recalls if necessary. |

FAQ about threaded rod:

1.What’s the price of class 10.9 threaded?

In general, our class 10.9 threaded rods are made of 40cr or 42crmoAISI4140/42CRMO4) alloy steel. The price is made up of materials, processing, packaging and labor costs. We are focused on the production, the main customers are for wholesalers, distributors, large end user. Committed to making our customers profitable. The wholesale price of 10.9 class bolts is 1500-2000usd/ton. The material price of steel will fluctuate frequently, and the price is different for different surface treatment/quantity, so please send the inquiry to our email for the specific price. Emai: info@china-bolts.com

2.How many days does it take you to deliver a container of threaded rods?

Our daily production capacity is about 20 tons, but due to the arrangement of materials, heat treatment, surface treatment, order scheduling takes time. The average delivery time of threaded rods for a container is 30-40 days.

3.What countries do you export your threaded rods to? Whether mechanical properties can be guaranteed.

We exported threaded rods to United States, Germany, Russia, Poland, Spain, Brazil, Argentina, Vietnam, Canada, Australia, UAE, Saudi Arabia and other countries for more than 10 years. Metric threaded rods are guaranteed to meet the mechanical properties specified in ISO898-1. American Standard threaded rods are guaranteed to meet SAE J429 or other ASTM mechanical performance requirements.

4.Can you provide samples of threaded rods?

Yes, we have some stock in regular sizes. Samples can be provided free of charge. But the customer needs to bear the freight.

5. Do you have a minimum order quantity requirement?

Yes, the MOQ we usually produce is about one ton. But we have most sizes in stock, so for inventory items, even 10 units we can supply.